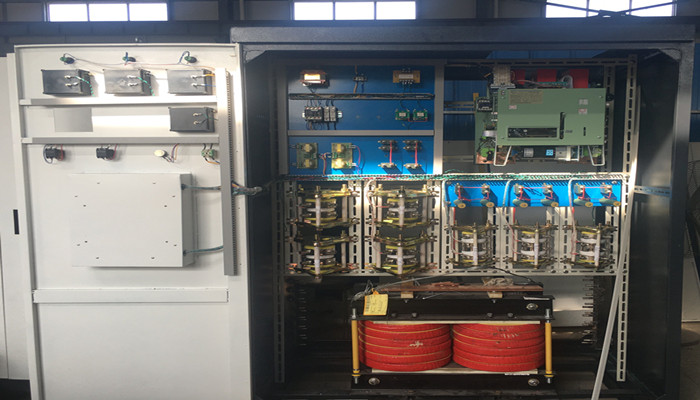

1.Digital IGBT induction heating machine

2.The intelligent power switching system

3.Crankshaft connecting rod power conversion system

4.Multiple thin crankshaft quenching transformers and induction coils

5.Automatic material loading unloading mechanism.

6.Crankshaft clamping and deformation limiting mechanism

7.Crankshaft rotary setting mechanism

8.Hardening water and cooling water system.

9.CNC system, the touch screen operation

1.Automatic monitoring and protection of temperature, pressure, and flow of quenching fluid and cooling water.

2.The control system has the functions of fault protection, indication, and alarm.

3.Crankshaft moving system: servo motor and ball screw are used to drive the crankshaft to move laterally, and a rectangular linear guide rail is used.

4.Load feed: Load rise and fall power for the cylinder.

5.The machine is equipped with 6~15 load systems (including quenching transformer, capacitor, induction coil, etc.), and each load can be switched to work independently in turn. The distance between transformers can be manually adjusted from 0mm-100mm.

6.Process parameters of load work can be set independently.

7.The clamping process of the crankshaft is completed automatically. The clamping length is adjusted by the electric lead screw.

8.The induction heating machine part has perfect self-protection functions.

9.Process parameter monitoring can monitor and record the heating parameters of each heating part.

Induction hardening machine is mainly used for the gear, shaft, guideway, roller, camshaft, crankshaft hardening jobs.

|

Model/Item |

FHCH-A |

FHCH-B |

FHCH-1/5-18 |

FHCH-2/7-18 |

|

Max. Crankshaft swing diameter(mm) |

500 | 1000 | 300 | |

|

Max. Crank throw radius(mm) |

200 | 500 | 80 | |

|

Max. Crankshaft length(mm) |

3000 | 10000 | 1500 | |

|

Heating Machine power(KW) |

750 | 1500 |

200*1 |

200*2 |

|

Part hardening method |

Immersion liquid |

Spraying liquid |

||

|

Heating coil cooling( set) |

High pressure strong cooling |

|||

|

Heating power cooling (set) |

Closed-loop soften water cooling |

|||

|

Hardening medium inner cycling cooling(set) |

Closed-loop hardening medium cooling |

|||

|

Outer cycling cooling |

Industrial refrigerating unit |

|||

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

5.What are your payment terms?

Pay 30% T/T as advanced payment, the balance amount can be paid before shipment.

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get Started

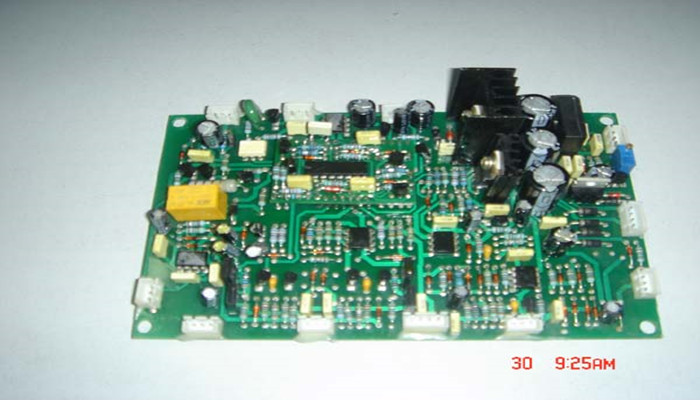

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible