The shallower the quenching layer is, the higher the frequency should be.

1. Hardening depth below 1mmshould use a frequency range 100-500KHZ.

2. Hardening depth 1-2.5mm should use a high-frequency range 20-100KHZ.

3. Hardening depth above 2.5mm should use a medium frequency range 0.1-20KHZ.

Oscillating frequency can be 100KHZ -15MHZ, effectively control the depth of surface heating .

It can continuously work for 24h with 100% duty cycle.

The main components all imported from famous brand.

Small volume, light weight, high effective, environmental protection.

|

Model |

FHC-08 |

FHC-16 |

FHC-40 |

FHC-70 |

FHC-100 |

FHC-150 |

FHC-300 |

|

Input voltage |

380V±10% |

||||||

|

Input power |

8KVA |

16KVA |

40KVA |

70KVA |

100KVA |

150KVA |

300KVA |

|

Max.input current |

37A |

24A |

60A |

115A |

150A |

225A |

450A |

|

Oscillating frequency |

100-600KHz |

||||||

|

water pressure |

0.15-0.30MPa |

||||||

|

Resonance mode |

Series resonance, parallel resonance |

||||||

|

Control precision |

0.1% |

||||||

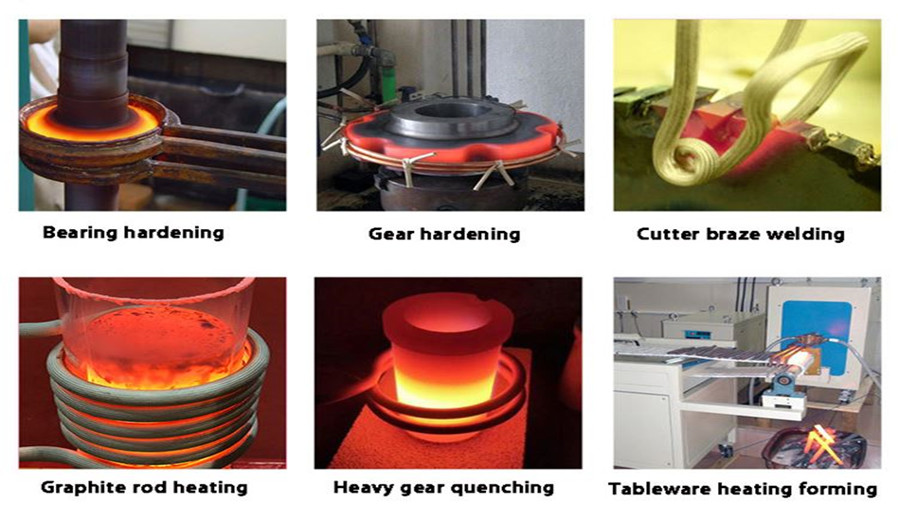

1. Gear and shaft quenching ,inner hole quenching, quenching depth can be within 2mm.

2. Carbon steel and stainless steel screw coating.

3. Continuously quenching for saw blade, annealing and quenching for thin wire.

4. Welding for carbide saw blade, carbide tips, communication cable and filter capacitor.

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

5.What are your payment terms?

Pay 30% T/T as advanced payment, the balance amount can be paid before shipment.

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

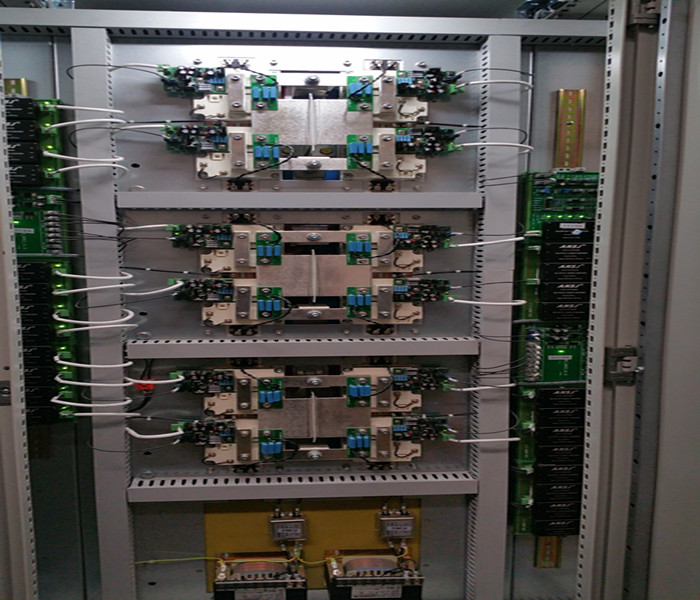

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

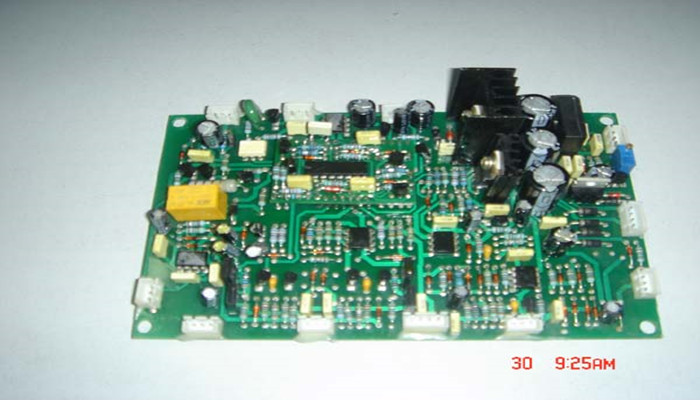

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible