Digital technology is a technology that transforms various information into computers recognized language for processing storage, analysis and transmission.

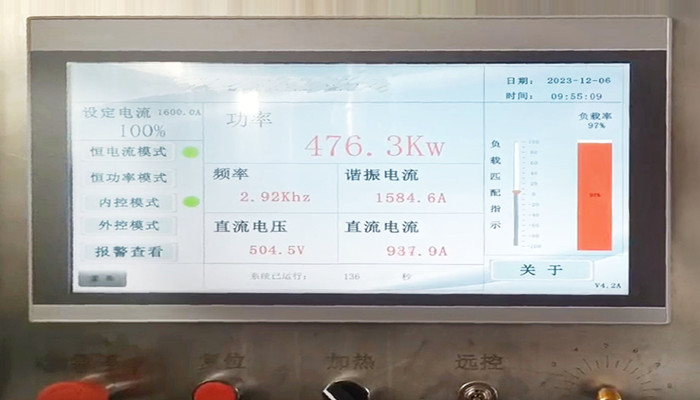

1.Multi-segment temperature control.(Normal is 5 segments, can customize according to your requirement)

2.Heating time can be accurate to 0.1s, and current can be accurate to 1A.

3.Support parameter storage.

4.Rich communication interfaces, can access industrial bus such as RS-485,CAN and so on.

5.Various operation modes, like manual mode, automatic mode and temperature control mode. Real-time display of processing parameter,which is more intelligent on draw curve of current and frequency.

6.Interactive man-machine interface.

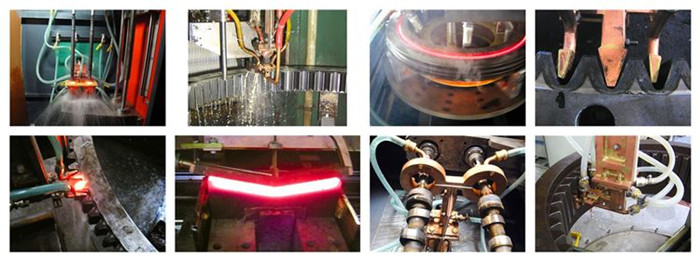

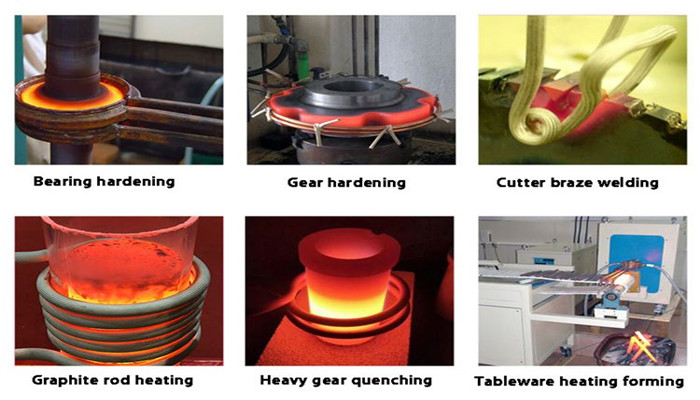

1.Shrinkage Fit mainly refers to the connection between different metals or metals and nonmetals through the heating of metals, using the principle of thermal expansion or thermal melting.

2.For example the computer radiator copper core and aluminum sheet, horn net buried value welding, steel plastic tube composite, aluminum foil seal (toothpaste), motor rotor, electric heat pipe seal and so on

3.Welding of various diamond composite drills, carbide tips, saw blade,knife and mining machinery accessories like drill bit,etc.

4.Welding of refrigeration equipment accessories, such as tube joints, sight glass,etc.

5.Welding of water-cooled belt joints and cold plates in the cooling system of the new energy vehicle power battery.

|

Name |

Digital Induction Heat treatment equipment |

|

Display content |

Time ,current, frequency, current-time curve |

|

Alarm interface |

Water lack, over current, over voltage, phase lack, over current, etc. |

|

Model |

FHG-40/FHG-60/FHG-120/FHG-160/FHG-1000 |

|

Output power |

40KW/60kW/120kW/160kW/1000KW |

|

Output frequency |

0.5-20KHZ |

|

Input voltage |

380V±10% |

|

Duty cycle |

≥97% |

|

Control core |

High performance DSP processor |

|

Operation interface |

Industrial touch screen + button |

|

Cooling ways |

A combination of water cooling and air cooling |

1. We are the top induction heating machine supplier, no agents.

2. We have strong technical team for 19 years product experience and make sure the delivery time.

3. The main components are mainly the international brand, stable and safe.

4. We have professional after-sales teams, and solve the customer problem in time.

1. Factory direct delivery goods.

2. 24 hours of technical service

3. 20 year experience in product making and application

4. In stock, 12 months warranty periods

5. Lifetime technical and accessory support

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

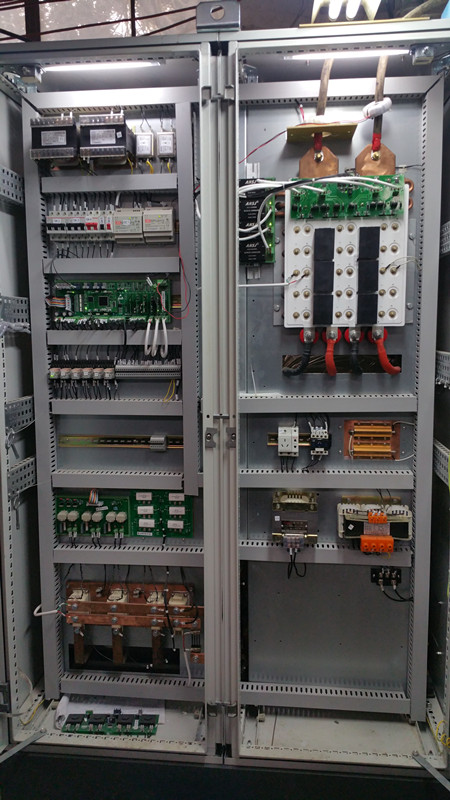

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get Started

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Melting equipment is mainly used for the steel, alloy steel, cast iron and other ferrous metal materials and stainless steel, copper, aluminum, zinc and other non-ferrous metal material smelting.

Medium frequency pipe bender adopts medium frequency induction heating machine heating to bend the workpiece under the condition of local heating.

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible