Our full automatic intelligent IGBT high frequency induction annealing machine power is from 50kw-400kw, with frequency range 50Khz-200Khz, the power factor is more than 0.95.

Based on the obvious difference in technical level and characteristics between IGBT high-frequency power supply and vacuum tube power supply, the selection of IGBT high frequency power supply takes the quenching depth, copy distribution, and other requirements as technical indexes, rather than the frequency of traditional vacuum tube power supply as technical indexes.

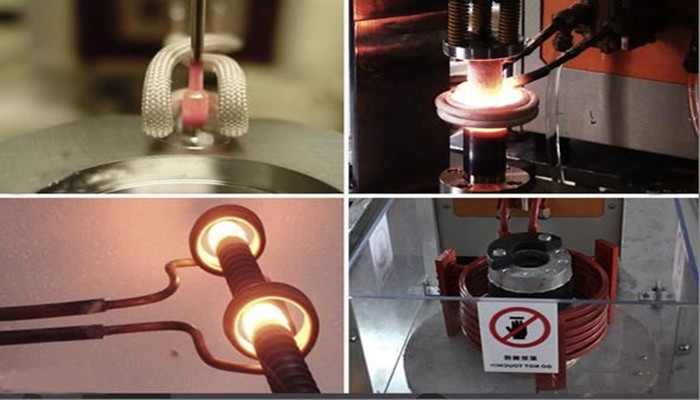

1.All kinds of auto parts annealing, like a shaft, gears, and other parts.

2.All kinds of stainless steel online annealing application.

3. Precision hardware parts annealing.

4.All kinds of wire online annealing

1.Tell us your annealing parts details, drawings will be adopted, then your request on the annealing process, our technical team will make a basic technical proposal for you.

2.If the parts annealing, the buyer can provide the heated parts to us, we can first test the heated parts annealing process and then make a conclusion for the whole process.

3.After confirming which model induction annealing machine finishes the parts request job. We will quote you accordingly and also will provide the whole heat treatment technical process of the Induction annealing machine for you.

Delivery time: in 10-15 working days.

Warranty period: 12 months.

Payment terms: 30% T/T, before shipment 100% T/T should be paid.

Package: plywood cases.

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

| Name |

IGBT Induction Annealing Machine |

|||

|

Display content |

Time ,current, frequency, current-time curve |

|||

|

Alarm interface |

Water lack, over current, over voltage, phase lack, over current, etc. |

|||

| Model |

FHG-40 |

FHG-120 |

FHG-600 |

FHG-1000 |

|

Output power |

40Kw | 120KW | 600KW | 1000KW |

|

Output frequency |

0.5-20KHZ | |||

|

Cable length |

3-30M | |||

|

Input voltage |

380V±10% |

|||

|

Operation interface |

Industrial touch screen + button |

|||

|

Cooling ways |

A combination of water cooling and air cooling |

|||

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

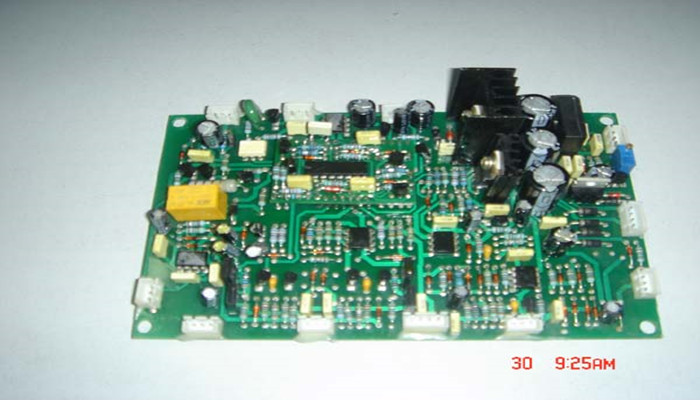

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible