1. 100% full load, 24 hours continuously working.

2. All-solid-state IGBT frequency conversion and function adjustment, realizing frequency conversion automatic tracking.

3. Small volume, save the production area.

4. Safety operation, without any high voltage

5. Safety operation, without any high voltage

|

Model |

Input power |

Output voltage |

Oscillation frequency |

Duty cycle |

|

FHZ-25 |

25KW |

70-550V |

200-2000KHz |

24 hours continuous working |

|

FHZ-45 |

45KW |

70-550V |

200-2000KHz |

|

|

FHZ-70 |

70KW |

70-550V |

200-2000KHz |

|

|

FHZ-110 |

110KW |

70-550V |

200-2000KHz |

|

|

FHZ-160 |

160KW |

70-550V |

200-2000KHz |

|

|

FHZ-240 |

240KW |

70-550V |

200-2000KHz |

|

|

FHZ-500 |

500KW |

70-550V |

200-2000KHz |

Heating molds, Hardening all kinds of parts, like shaft and gear, preheat pipe before welding, melting all metals, billet rod, tube induction forging.

Our medium frequency induction heating equipment has wide application ranges during the productions. As per the customer’s technical request, we do the different induction heating technical designs to meet different application fields. But the medium frequency induction heating equipment mainly used in the following fields.

1.We are the top induction heating machine supplier, no agents.

2.We have strong technical team for 19 years product experience and make sure the delivery time.

3.The main components are mainly the international brand, stable and safe.

4.We have professional after-sales teams, and solve the customer problem in time.

Delivery time: in 10-15 working days.

Warranty period: 12 months.

Payment terms: 30% T/T, before shipment 100% T/T should be paid.

Package: plywood cases.

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

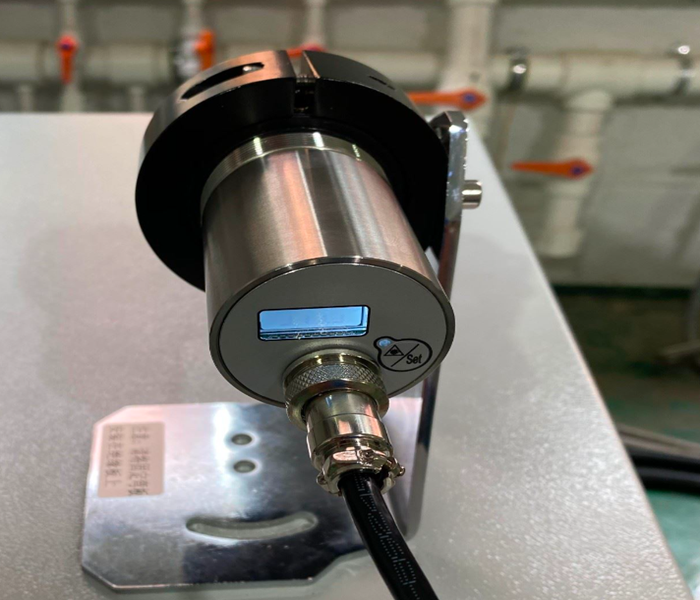

Infrared temperature measuring device is a kind of non-contact equipment that uses infrared radiation principle to measure the surface temperature of objects. It detects the infrared radiation energy emitted by the object, converts it into temperature readings, and is widely used in industrial, medical, scientific research and other fields.

Get Started

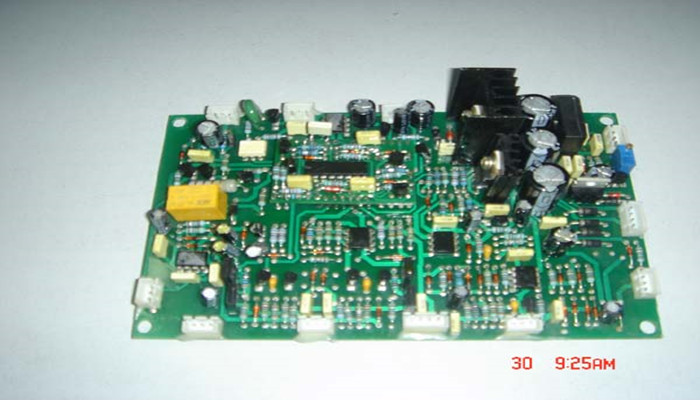

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Fill in the information and we will contact you as soon as possible