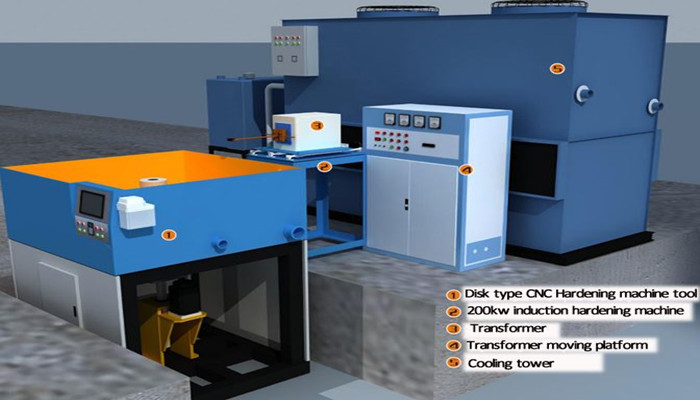

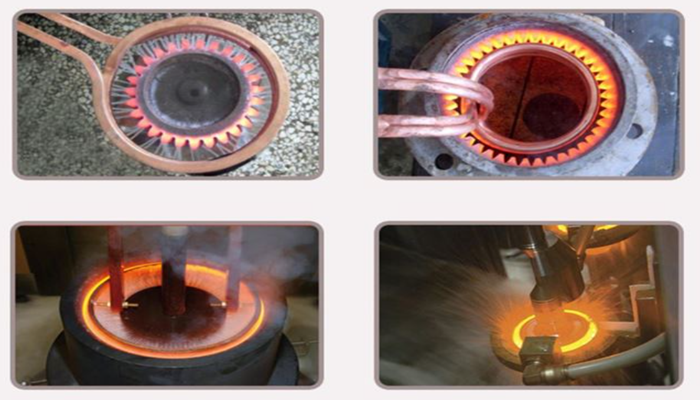

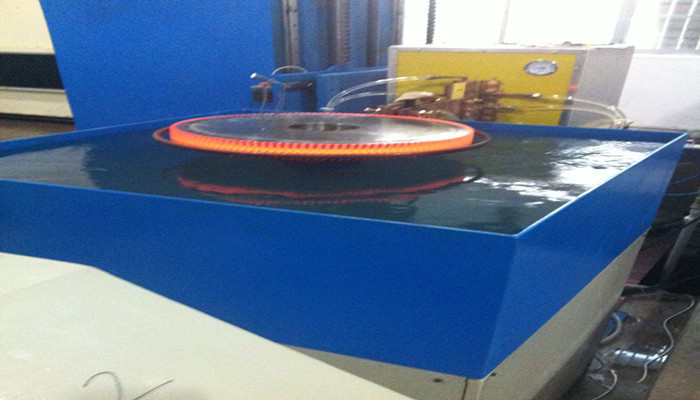

Gear Hardening Machine consist of induction heating machine, CNC hardening machine tool, cooling water, transformer, induction coils. According to different parts request, changing the different induction hardening coils is OK.

1. Power: 18-2000KW

2. Frequency range: 0.1-600KHZ

3. Power adjust range: 1%-100%.

4. Minimum star-up time: 0.1S

5. Power stability: <0.1%

6. A variety of incoming voltage (380V/660V)

The machine tool is used for the workpiece hardening and tempering, like shaft, gear, disk type,etc. It has some function of continuous hardening, piecewise continuous quenching ,section simultaneous quenchine, etc.

It is mainly used to change the hardness of the metal material after the workpiece is heated. The specific application is as follows:

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get Started

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.Basic functional has three points as follow, such as circuit integration: the power supply, control, drive, filter and other circuits are integrated on one or more circuit boards. Signal processing: Processing sensor signals to achieve closed-loop control. Power distribution: Distribute and adjust power output to ensure heating effect. Protection function: Provides protection against over current, over voltage and overheating.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible