Please list the follow technical details to us, we could choose a suitable induction bolt heating machine.

1.Your workpiece material and heating temperature?

2.The heating speed request?The faster the heating speed, the bigger the machine power should be chosen.

3.The longer the machine works, the bigger the machine power is.

4.For the hardening, brazing process, the power can be smaller, the frequency is higher. For the annealing, tempering process, the power can be bigger, the frequency is lower.

Power range: 80-2000KW

Frequency range: 0.5-50KHZ

Power Factor: >0.96

Resonant mode: series, parallel, hybrid resonant

Control Precision: 0.1%

Resonance Mode: adjust voltage and power

1.Automatic billet feeding device, save energy, protection environment

2.Different shape billet just need to change different induction furnace, the furnace is easy to change.

3.Heating uniform, heating speed is faster.

4.Match with an independent cooling water circulation system to ensure the machine can 24 hours continuously working.

5.Perfect self-protection functions, like over-voltage, over heat, lack of water, lack of phase, etc.

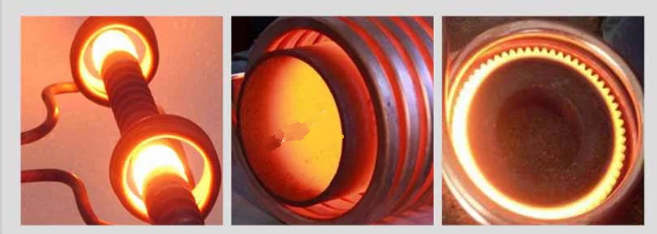

The induction bolt heating machine is mainly used in the diathermy heating forging various round steel, square steel, bar material, round cake billet, round pipe, steel plate, steel ring, fastener, high-strength bolt nut, automobile U-shaped bolt nut, stainless steel bolt nut and so on.

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

5.What are your payment terms?

Pay 30% T/T as advanced payment, the balance amount can be paid before shipment.

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

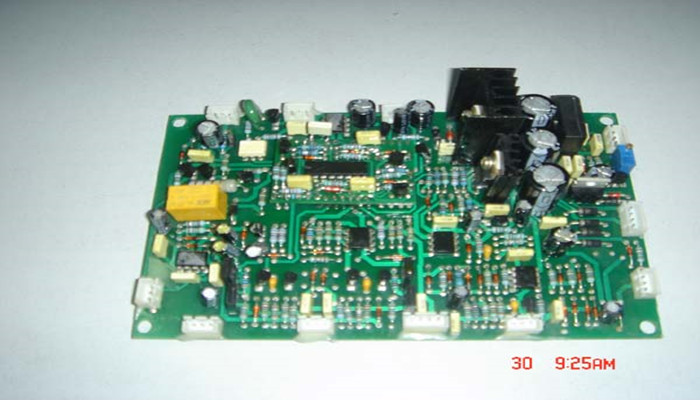

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible