Because induction tempering machine heating time is short, tempering temperature is raised appropriately. The workpiece after surface hardening could choose furnace inside tempering,self-tempering, or induction tempering. Induction tempering is adopts electromagnetic induction method to make the heated workpiece internal produce current. In order to reduce the tensile stress of the transition layer, heating depth is larger than the hardening layer. So, it is necessary to adopt a lower current or lower specific power to continuously heat the parts, extend the tempering time, make heating layer thicken. For the one-time heating workpiece, heating layer can be thickened by intermittent heating.

1. Power range: 8KVA—300KVA

2. Frequency range: 0.5KHz—500KHz

3. Fast heating speed and high heating efficiency.

4. Work pressure: 0.15MPa—0.30Mpa

1.The quenching heating time is measured in seconds, and the production cycle is short.

2.Induction heating tempering is more convenient to form a production line, more conductive to the realization of mechanization and automation. High frequency heating device can be used for the local tempering of the thin parts.

3. Can do the local tempering jobs, the heating time is shorter. There are little oxide skin and little deformation.

Our induction heaters are mainly used for the following metal heating fields.

1.Mainly used for the shaft, gear hardening, inner hole hardening, hardening depth can reach less than 2mm.

2.Carbon steel screws and stainless steel screws heated glue.

3.Saw blades continuous quenching, stainless steel, and alloy steel filaments annealing or quenching.

stainless steel tempering.

In the short time induction tempering process, the heating time and temperature are key parameters. In order to make sure the machine could reach your request, Please pay attention to the following points.

1.The heating time and the energy transmitted to the parts are strictly monitored to ensure that the residual heat is stable in a certain range.

2.Coolant flow, time and cooling temperature are also monitored to ensure consistency of the workpiece surface temperature after reheating with quenching waste heat.

3.If the workpiece shape is complex or scanning heating , it is not easy to temper. The heart temperature is not uniform. The heat storage and heat absorption must be the same everywhere in the second surface layer of the hardened workpiece.Otherwise, the temperature is different after the heat preservation, so there is no self-tempering that can be carried out.

1.How can I get your installation service?

For simple machine, we will provide installation instructions and videos. For complex products, if you need, we will arrange for a skilled engineer to provide door-to-door guidance.

2.What is your fastest delivery time?

Normally one week after getting the payment.

3.What is your power range?

Our induction heating machine power range is from 20-600kW.

4.What is your machine application range?

Used in metal heat treatment, brazing, forging ,melting,etc.

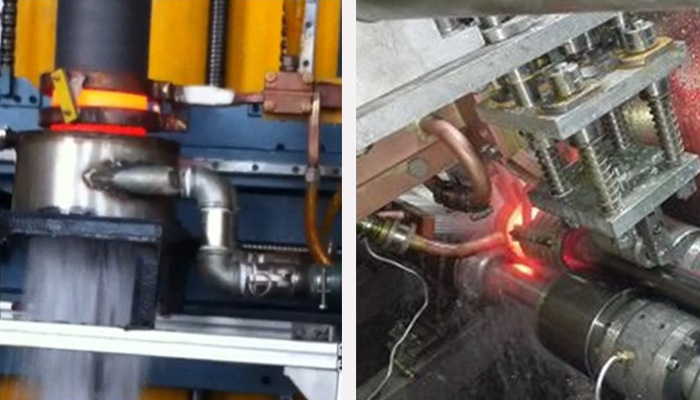

Induction tempering machine details : Power module provides high frequency alternating current, usually using IGBT or MOSFET and other power devices. Induction coil produces alternating magnetic field, shape and size according to the workpiece design. Control system adjust frequency, power and other parameters to achieve accurate control. Cooling system to prevent equipment overheating, commonly used water cooling or air cooling.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get Started

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible