Industrial melting furnace adopts the isolated transformer, compared with the compensatory capactive melting furnace, eliminates the danger of 10,000 volts high pressure, and ensures personal safety.

|

Model |

Melt Steel/Iron |

Melt Aluminum/ |

Melt Copper/Gold/Silver/ |

|

FHZ-45KW |

18KG |

18KG |

50KG |

|

FHZ-70KW |

25KG |

25KG |

100KG |

|

FHZ-90KW |

40KG |

40KG |

120KG |

|

FHZ-110KW |

50KG |

50KG |

150KG |

|

FHZ-160KW |

100KG |

100KG |

250KG |

|

FHZ-200KW |

150KG |

150KG |

350KG |

|

FHZ-300KW |

200KG |

200KG |

500KG |

|

FHZ-500KW |

250KG |

250KG |

600KG |

1.Comparing to electronic tube, it saves 50% energy;comparing to thyristor,it saves 20% energy.

2.Low cost of making induction coils, wide-matching performance,various function of technological planning, making your usage more freely.

3.Small volume,light weight , easy to remove, it has non high voltage, make operation more safely.

4.Digital auto-control, it has the function of manual, semi-auto,full-auto and heating-keeping-cooling divide period to control.

5.Perfect function of protect itself, such as over-voltage, over-current, lack of water, phase fail,over hot,etc.

6.Auto tracking frequency itself,the power can be adjusted to max.

7.Special cycle cooling system, make sure the machine work continuously.

The induction bolt heating machine is mainly used in the diathermy heating forging various round steel, square steel, bar material, round cake billet, round pipe, steel plate, steel ring, fastener, high-strength bolt nut, automobile U-shaped bolt nut, stainless steel bolt nut and so on.

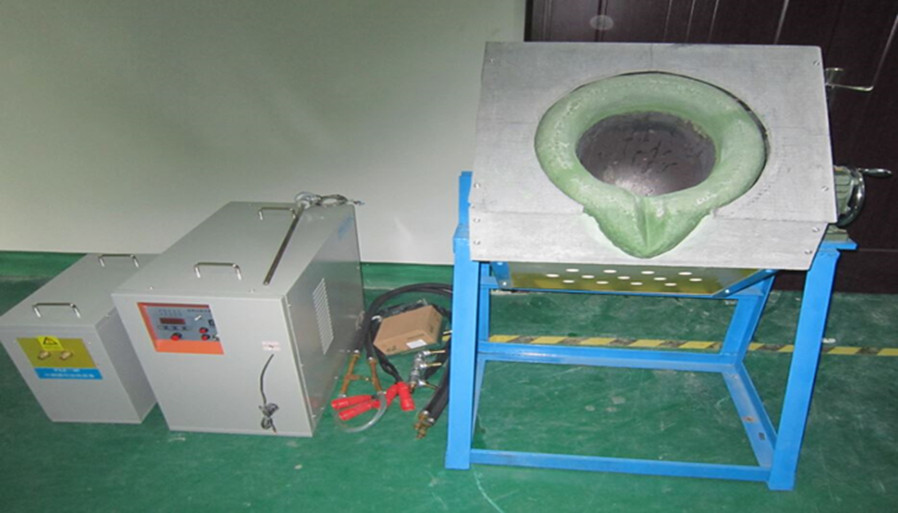

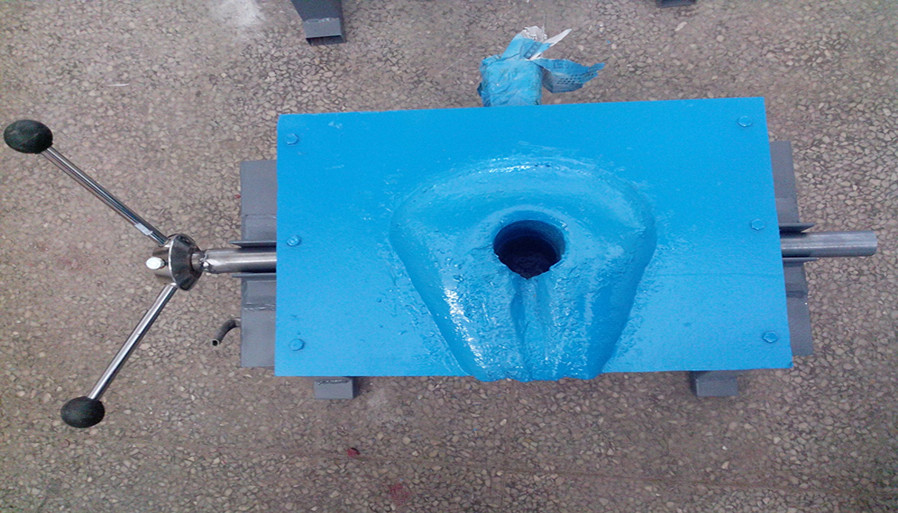

The Medium Frequency Melting Furnace adopts high strength steel body with over pressure, over current, and overload protection device. Production safety life is longer. Smelting waste iron, steel, stainless steel, copper, aluminum, and other metals. Our products are exported all over the world and can be customized according to local voltage and smelting needs.

1.Factory direct delivery goods.

2.24 hours of technical service online

3.Free workpiece test and send test result to you.

4.19 year experience in product making and application.

5.In stock, 12 months warranty periods

6.Lifetime technical and accessory support

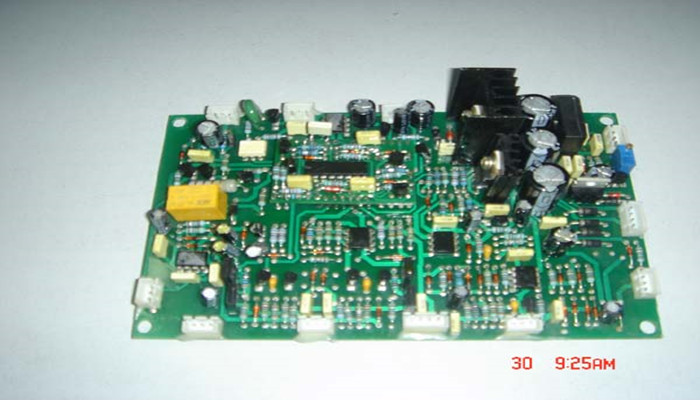

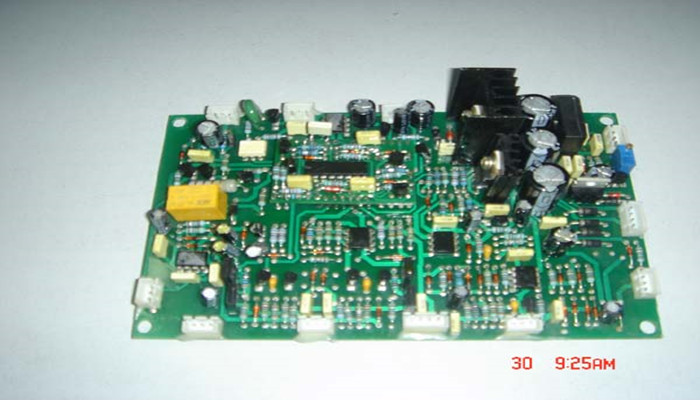

The drive board is one of the core components of induction heating equipment, which is responsible for controlling the power output and heating process.

Get Started

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible