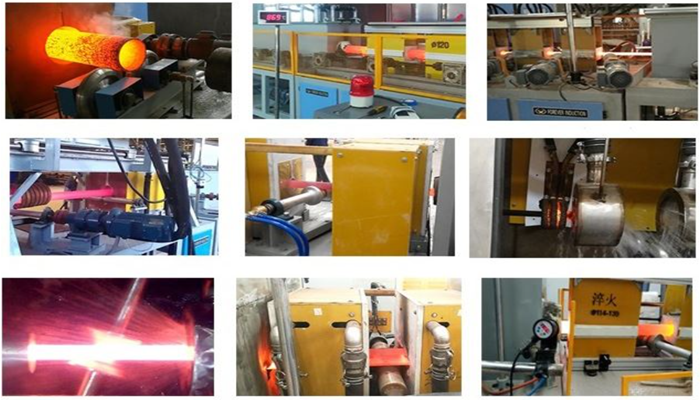

Surface hardening equipment frequency range is 0.1-20KHZ. It is mainly for standard parts forging, metal melting, motor rotor heating, steel tube end expanding, billet heating, medium frequency hardening, preheating and tempering etc.

1. Power range: 8-300KVA

2. Frequency range: 0.5-500KHz

3. Input power: three phase 380±10%, 50Hz; 480V, 60Hz

4. Facilitate mechanization and automation.

1. We have a strong team, and they have in the surface hardening machine field for more than 15 years.

2. With Siemens PLC control center, combine the perfect program design, reach the fully automatic production.

3. 3.High precision infrared temperature measuring device, the temperature control precision reach 0.5%

4. Facilitate mechanization and automation.

1.Please tell us your heated part details, drawing will be better.

2.For simple parts, we will suggest machine type for you. For the complex part, you’d better send me some samples, so we could do some test to conclude the final heat treatment technical process.

3.According to your budget, you could choose automatic or half manual induction heating system.

4.We also give you some suggestion to help you know suitable hardening solution.

1.Used for quenching,tempering and other heat treatment field.

2.Used for hot forging.

3.It is used for preheating welding aid and post-welding heat treatment of large workpiece welding.

4.Used for annealing field on all kinds of metal materials.

5.Used for hot matching and hot sleeve occasions.

6.Used for metal melting, plate heating.

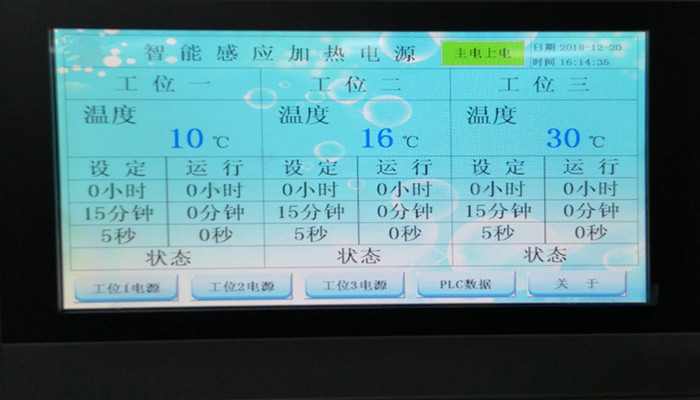

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible