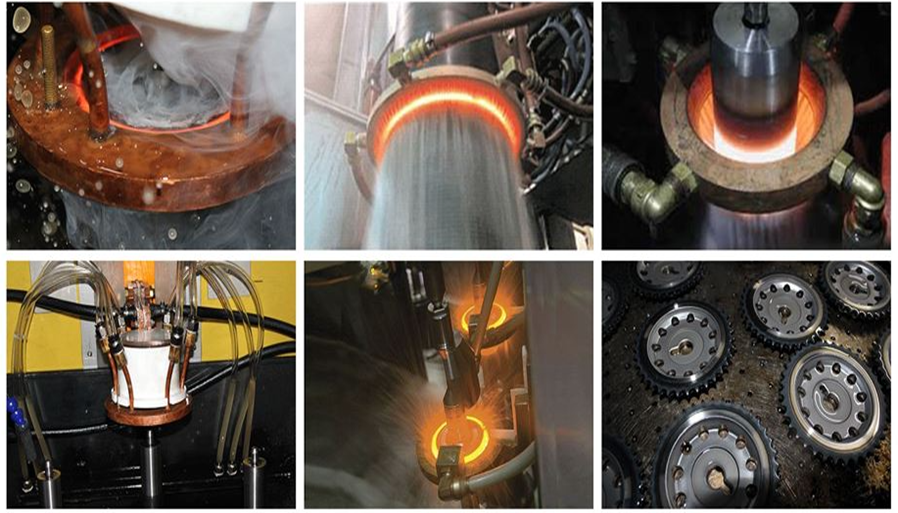

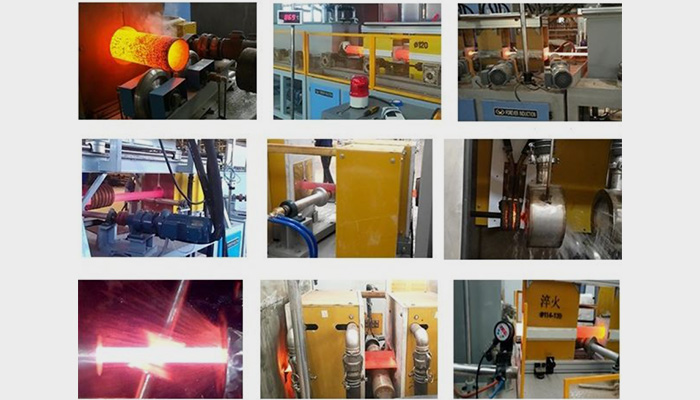

The vertical solid high frequency quenching machine is one of the complete set induction heating machine of our company.It mainly applied processing axis class and the gear components, but also the plate class components and the peculiar part.It adjust the high/medium frequency power source using the spray coolant conditions, can meet factory’s normal request. For the hydraulic pressure actuation, the electrical control semiautomatic machine, mainly used in quenching, annealing or the fire working procedure. It has manual, full-automatic function, simple operation and easily to learn.

1. The rotation speed can set any interval to meet the diameter differences on one work piece.

2. The quenching range setting is accuracy.

3. The hardening depth can meet technical requirements, similar with non-oxidative quenching.

4. Small deformation of work piece.

5. Good repeatability,easy to quench multiple local work piece.

|

Total Power |

2KW |

Rotation Speed |

0-200r/min |

|

Max. Piece Length |

500-1000mm |

Return Speed |

2-50mm/s |

|

Maximum Piece Diameter |

300mm |

Weight |

350KG |

|

Max. Piece weight |

20KG |

Dimension |

1100X650X1450mm |

|

Moving speed |

2.5mm/s |

Cooling method |

Spray/extract(option) |

Vertical solid high frequency quenching machine is a key equipment for metal heat treatment, mainly used for quenching, tempering and other processes.

1.Can you send engineers to us for technical installation?

Yes, we can.But you must guarantee our engineer personal safety.

2.After the warranty period, what kind of service do you support?

We will keep on providing the technical service and machine regular maintenance service.

3.How can I get your installation service?

For simple machine, we will provide installation instructions and videos. For complex products, if you need, we will arrange for a skilled engineer to provide door-to-door guidance.

The vertical induction hardening machine can realize the workpiece induction quenching and tempering treatment at the same machine and can realize the online production arrangement.

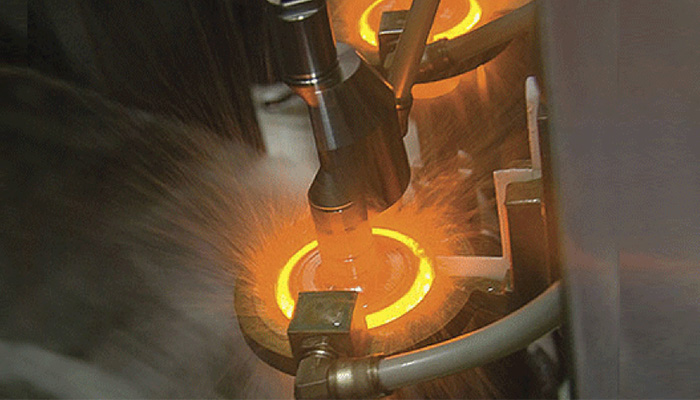

It has the functions of continuous quenching, simultaneous quenching, section continuous quenching, section simultaneous quenching, and induction coil feeding mobile quenching functions.

It is mainly suitable for the induction quenching and tempering treatment of gear shaft, driveshaft, steering rack tooth surface, tooth back, etc.

1. We are the top induction heating machine supplier, no agents.

2. We have strong technical team for 19 years product experience and make sure the delivery time.

3. The main components are mainly the international brand, stable and safe.

4. We have professional after-sales teams, and solve the customer problem in time.

1. Factory direct delivery goods.

2. 24 hours of technical service

3. 20 year experience in product making and application

4. In stock, 12 months warranty periods

5. Lifetime technical and accessory support

The display screen is the core part of the control system and is used to monitor and operate the quenching process. Its functions include real-time monitoring, operation control, fault alarm and data recording.

Get Started

The workpiece holding device of the quenching machine tool is the key component to ensure the stable position and attitude of the workpiece during the quenching process. Its functions are fixed workpiece, accurate positioning, fast loading and unloading. It is essential to ensure the stability and accuracy of the workpiece during the quenching process.

Get Started

The PLC automatic control display is the core part of the control system and is used to monitor and operate the quenching process. Its functions include real-time monitoring, operation control, fault alarm and data recording.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Melting equipment is mainly used for the steel, alloy steel, cast iron and other ferrous metal materials and stainless steel, copper, aluminum, zinc and other non-ferrous metal material smelting.

Medium frequency pipe bender adopts medium frequency induction heating machine heating to bend the workpiece under the condition of local heating.

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible