1. Big power, low frequency and good diathermancy.

2. High efficiency, energy saving, easy installation and operation.

3. 100% duty cycle,can work continuous for 24 hours.

4. The digital phase locked realizes frequency automatically tracking.

5. Complete protection function when over voltage, over current, over heat, lack of water and phase fail, machine automatically alarms and stop working.

6. Induction’s speed, precision, energy-efficiency make it the nature choice for metal heating.

|

Model |

FHZ-40 |

FHZ-80 |

FHZ-120 |

FHZ-160 |

FHZ-200 |

FHZ-400 |

FHZ-600 |

|

Output voltage |

380V±10% |

||||||

|

Input Power |

40KVA |

80KVA |

120KVA |

160KVA |

200KVA |

400KVA |

600KVA |

|

Max. Input current |

60A |

120A |

180A |

240A |

300A |

600A |

900A |

|

Oscillating Frequency |

0.1-30KHZ |

||||||

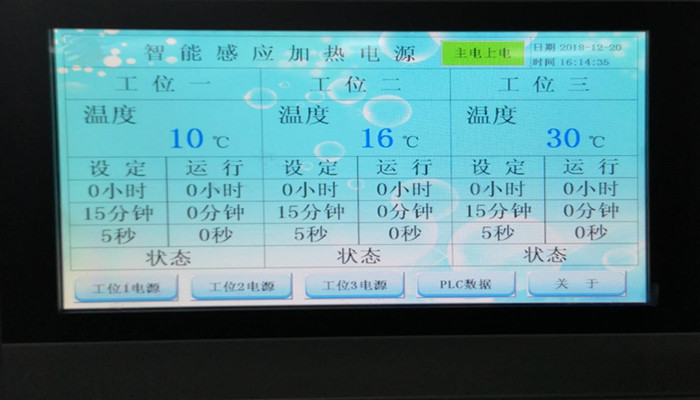

Infrared thermometer and energy control instrument.The temperature could control within ±2℃.

When heating standard parts,fasteners for forging , if diameter more than 20mm,medium frequency is proper. If use HF this time, modules must be heated melting external,but internal not heated.So it’s not effective,also age of mold induces,the cost increase a lot.

1.We are the top induction heating machine supplier, no agents.

2.We have strong technical team for 19 years product experience and make sure the delivery time.

3.The main components are mainly the international brand, stable and safe.

4.We have professional after-sales teams, and solve the customer problem in time.

1. Delivery time: in 10-15 working days.

2. Warranty period: 12 months.

3. Payment terms: 30% T/T, before shipment 100% T/T should be paid.

4. Package: plywood cases

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

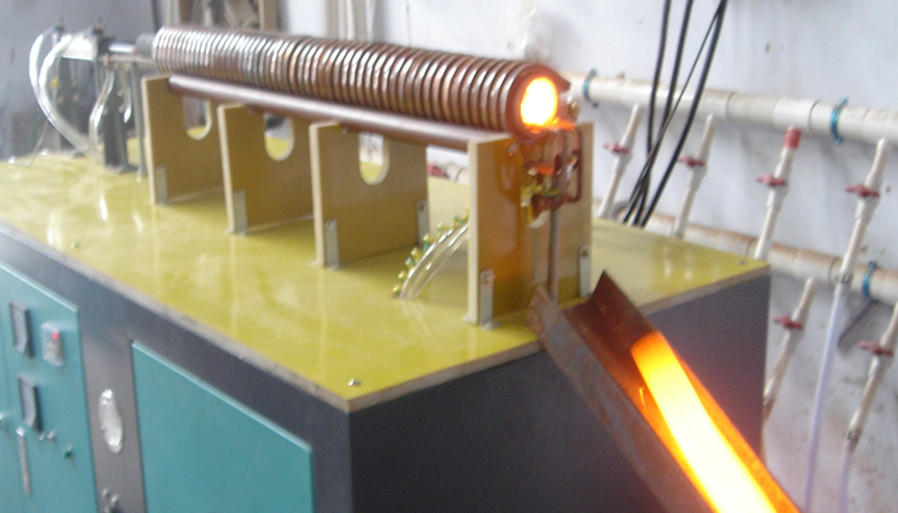

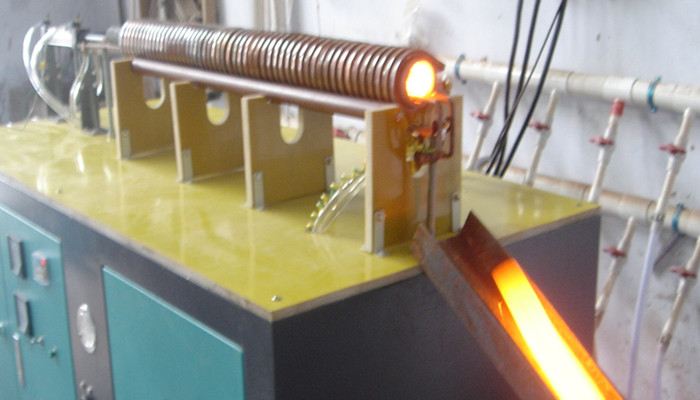

Induction forging furnace is the core component of induction heating equipment, which is responsible for generating alternating magnetic field to induce eddy current inside the metal workpiece and heat. Main structure: Coil material: usually high conductivity copper pipe, internal cooling water to prevent overheating. Coil shape: According to the shape of the workpiece design, common spiral shape, flat shape, ring and so on. Insulation: The coil surface is coated with insulation to prevent short circuits and arcing.

Get Started

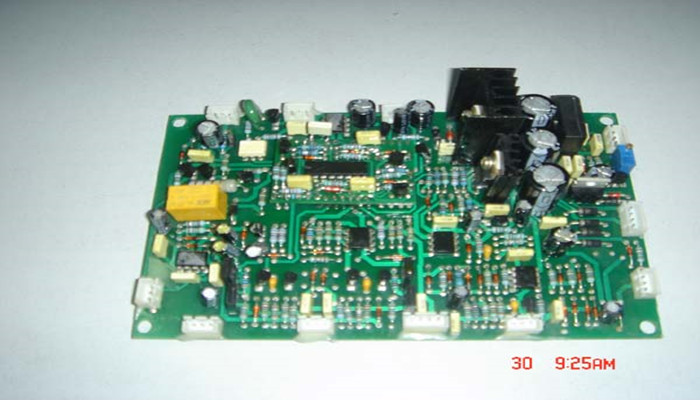

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible