Most of our machines are standard ones. In order to give you suitable induction heater model, we need to know the following heated parts details, so that we can help you find the best machine solution.

1. Heating workpiece material and size?

2. The purpose of heating and heating temperature?

3. Heating time request and other request?

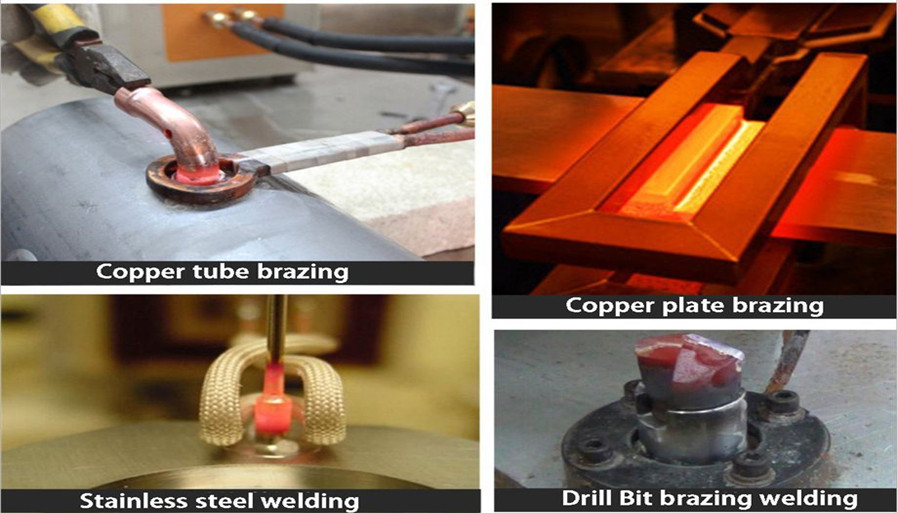

Induction brazing is a welding method by using high frequency, medium frequency, or power frequency induced current as a heat source. The induction welding machine uses the induction current (eddy current loss) generated by the conductor under the action of high frequency magnetic field and the magnetic field inside the conductor (hysteresis loss) to cause the conductor to heat itself.

According to the different heating frequency, it can be divided into high frequency induction heating (high frequency welding machine) and medium frequency induction heating (medium frequency welding machine). Because of the high heating speed and less metal burning loss, the joint process of induction brazing is highly consistent.

It is widely used in: pipe, shaft, rod, plate welding; A large number of applications in air conditioning, automotive, military, bathroom accessories, valves, and other industries.

1. Overheat of saw tooth, and can also prevent tooth from failing off caused by lack of complete penetration.

2. Can weld saw blade with high-performance and high –hardness saw teeth.

3. Providing welding technology and kits which can be used only after easy installation.3.

4. Compared into thyristor medium frequency furnace, is saves 10%–30% energy

5. Scientific design of induction coil to ensure convenient output of big power equipment,energy-saving and operation.

Mobile induction brazing machine is applicable to induction brazing, induction heating installation, thermal removal, special quenching, and other fields, widely used in power plants, transformer plants, railway electric locomotives, air conditioning refrigerator compressors, and other industries, suitable for copper, aluminum, stainless steel and other metal materials heating jobs.

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

5.What are your payment terms?

Pay 30% T/T as advanced payment, the balance amount can be paid before shipment.

1. We are the top induction heating machine supplier, no agents.

2. We have strong technical team for 19 years product experience and make sure the delivery time.

3. The main components are mainly the international brand, stable and safe.

4. We have professional after-sales teams, and solve the customer problem in time.

1. Factory direct delivery goods.

2. 24 hours of technical service

3. Free workpiece test

4. 19 year experience in product making and application

5. In stock, 12 months warranty periods

6. Lifetime technical and accessory support

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get Started

Mobile induction coil is easy to operate and flexible. The power supply is matched with hand-held coaxial water-cooled cable and hand-held transformer, which has the characteristics of high energy density and small size of equipment.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Melting equipment is mainly used for the steel, alloy steel, cast iron and other ferrous metal materials and stainless steel, copper, aluminum, zinc and other non-ferrous metal material smelting.

Fill in the information and we will contact you as soon as possible