Brazing is the process of jointing two or more pieces of meta. Induction brazing is a new brazing technology, it is characterized by good working condition, high production efficiency, safe operation.

1.Can weld saw blade with high-performance and high –hardness saw teeth

2.Providing welding technology and kits which can be used only after easy installation.

3.Compared into thyristor medium frequency furnace, is saves 10%–30% energy

4.Scientific design of induction coil to ensure convenient output of big power equipment,energy-saving and operation.

5.Energy concentration, fast heating, fast response of current and power, automatic sensor adaptation.

6.The welding temperature can be automatically controlled, the PID program for the workpiece and process can be competent for the second level of constant temperature control.

1.Diamond saw blade, hard alloy cutting tools(milling cutter,drilling bit), mould mining tools,copper wire of transformer,etc.

2.The heated area of base metal is bigger, the power is higher. The heating time of the individual is faster, the power is higher.

1.We are a direct factory that can make sure the delivery time in time,no agent.

2.24 hours of technical service online

3.Free workpiece test and send test video to you.

4.19 year experience in product making and application

5.In stock, 12 months warranty periods

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

5.What are your payment terms?

Pay 30% T/T as advanced payment, the balance amount can be paid before shipment.

|

Item |

Contents |

Item |

Contents |

|

Input voltage |

3*380V+1*Zero Line |

Chip speed |

72MHz |

|

Frequency |

50HZ |

Heating current setting |

5 sections(can reach 32 sections) |

|

Rated apparent power |

(15-60)KVA |

Process parameters are set to encrypt or not |

Password lock |

|

Max. apparent power |

(18-72)KVA |

displayer |

3.5-inch true color display, resolution 320*240 |

|

Rated output power |

(12-60)KW |

Alarm interface |

Over current, over-voltage, lack water, lack phase, overheat alarm. |

|

Max. Output power |

(18-70)KW |

communication interface |

DB-9 and 4-core aviation plug |

|

main control chip |

ARM STM32 |

Environment temperature |

+5℃~+50℃ |

|

Cooling water pressure Min/Max |

4/6bar(depends on different coils) |

Cooling water quality-PH value |

7.0-9.0 |

|

Memo: |

|||

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

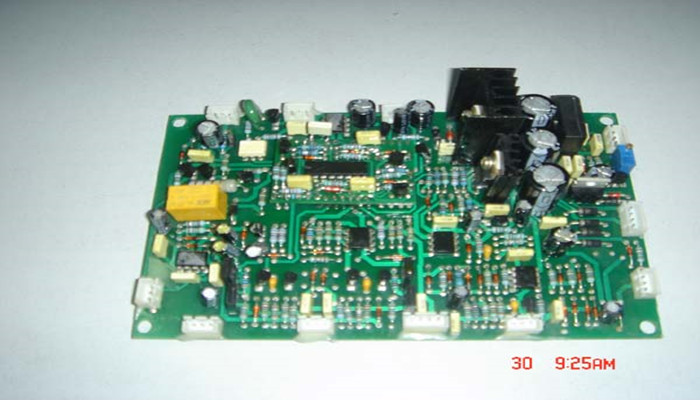

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible