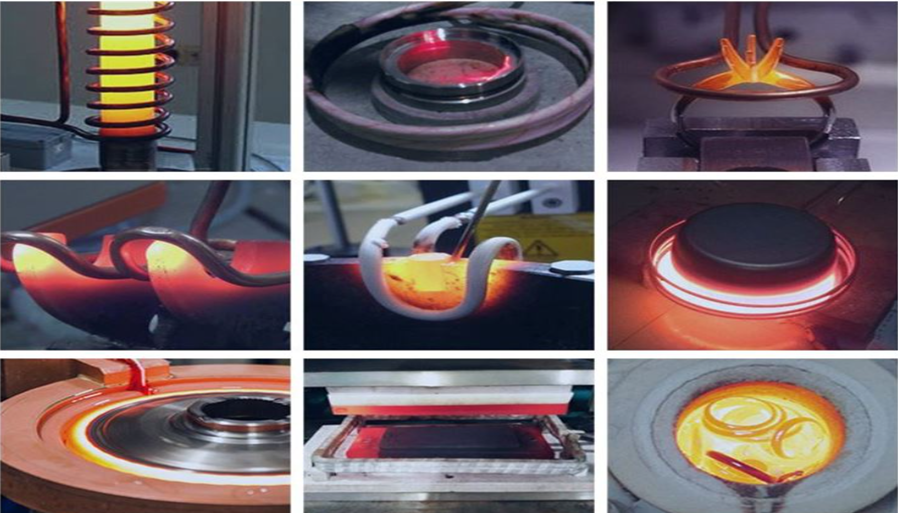

1.The frequency range of ultrahigh frequency welding machine is 100-800KHZ, can according to customer’s request do the machine. To realize the steel, stainless steel, copper tube, aluminum tube welding.

2.Has an extremely strong resistance network pressure fluctuation ability.

3.Adopt the imported high power resonant capacitor to obtain the stable resonance frequency, effectively improve the product quality, and realize the stability of the welding process.

4.There is no 10,000-volt high frequency voltage in the machine, which is limited to avoid radiation, interference, discharge, ignition and other phenomena.

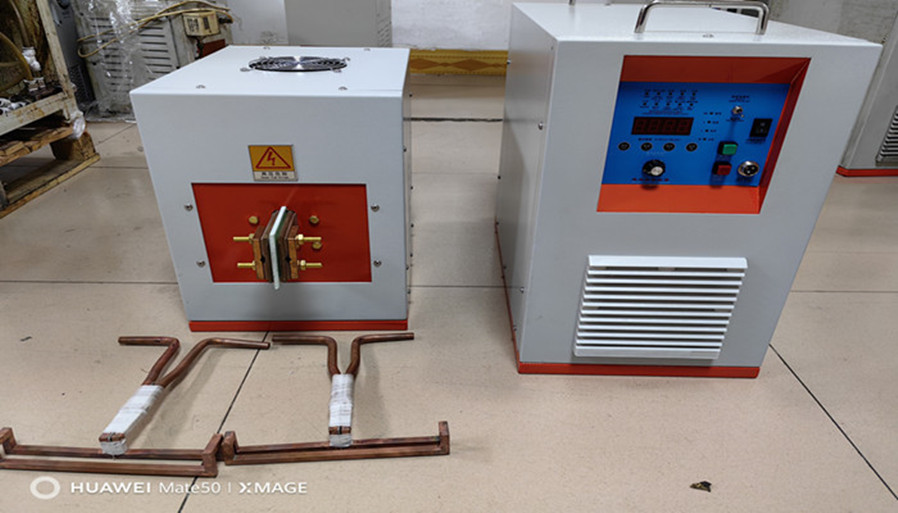

5.Small machine size, one body design, greatly saving the space.

6.Real all solid IGBT power regulation technology, realize the 100-800KHZ/3-300KW induction tube welding machine products.

|

Model |

Max output power (KW) |

Working Frequency Range(kHz) |

|

FHC-20 |

20KW |

200-500KHZ |

|

FHC-40 |

40KW |

200-500KHZ |

|

FHC-60 |

60KW |

200-500KHZ |

|

FHC-100 |

100KW |

200-500KHZ |

|

FHC-150 |

150KW |

200-500KHZ |

|

FHC-200 |

200KW |

200-500KHZ |

1. The cooling water should be clean and free of impurities. If the water quality is too bad, a filter should be added at the water inlet. Water shortage is strictly prohibited during working.

2. A short circuit of the induction coil should be prevented during operation.

3. The induction coil should be kept clean at all times, especially the multiple-turn induction coil to prevent a short circuit between turns, and the point of contact should be kept clean to prevent oxidation.

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

5.What are your payment terms?

Pay 30% T/T as advanced payment, the balance amount can be paid before shipment.

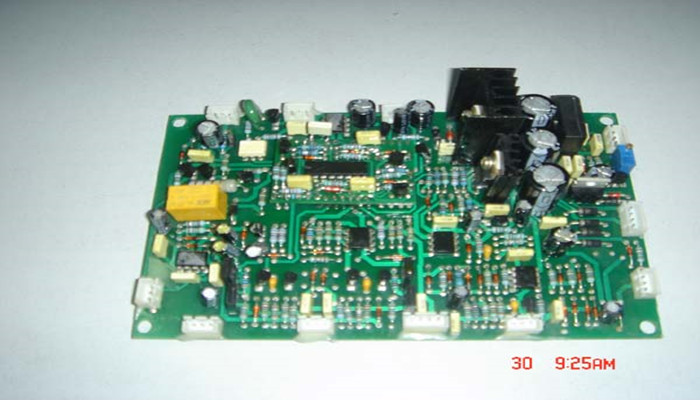

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).Basic functions have three points as follows. Noise filtering: Reduces electromagnetic interference at the input and output of the power supply.Harmonic suppression: reduces the impact of harmonics on the power grid and equipment.Voltage stability: Smooth voltage fluctuations to ensure stable operation of the device.

Get Started

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

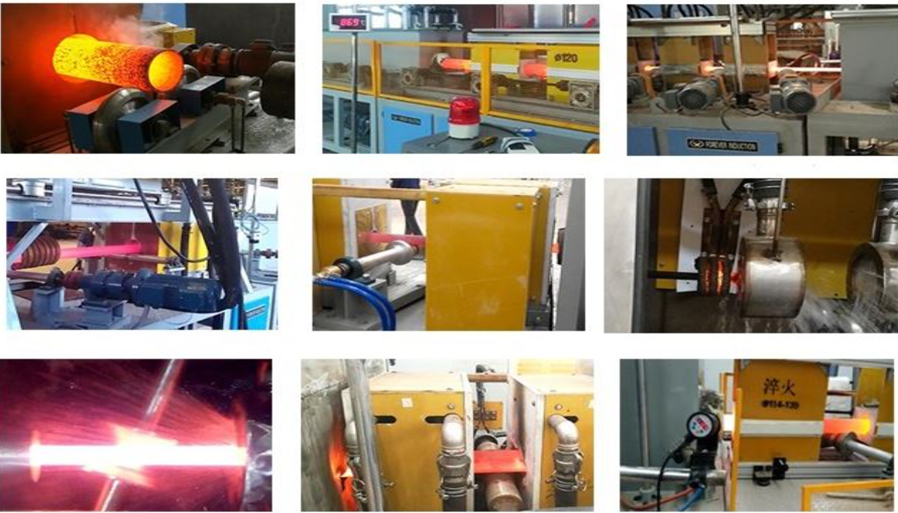

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Fill in the information and we will contact you as soon as possible