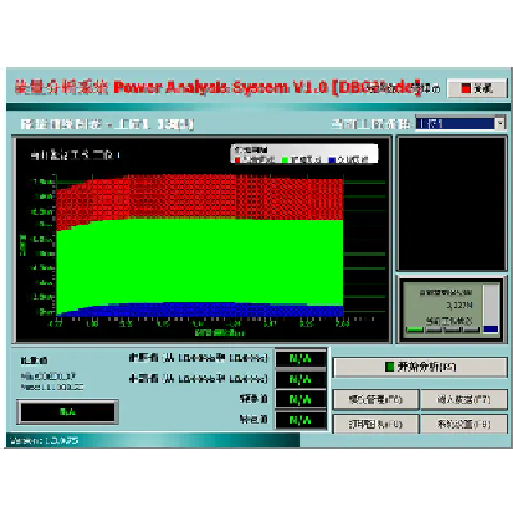

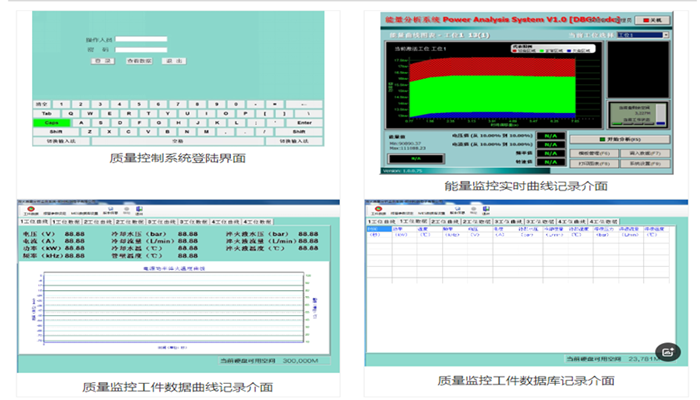

In induction heating, due to power grid fluctuations, environmental changes, the impact of human factors, for mass production quality is difficult to guarantee, and energy compensation monitoring system by setting the work piece heating qualified energy benchmark range, the work piece heating process to give the corresponding energy compensation, and display detection records, make the corresponding control, so as to ensure product quality.

In combination with infrared thermometer and PLC integrated control system , we have developed a more scientific and intelligent induction heating control system for some special needs f users,so that the heating temperature can be accurately controlled, the quality of heating products can be more stable ,the storage and reading of heating data, and the acquisition of heating curves can be more convenient, and it is convenient for customers to do research to materials and product characteristics. If you have higher heating requirements, welcome to discuss with us !

Delivery time: in 15-30 working days.

Warranty period: 12 months.

Payment terms: 50% T/T, before shipment 100% T/T should be paid.

Package: plywood cases.

Port:Shanghai, Tianjin.

1.We are the top induction heating machine supplier, no agents.

2.We have strong technical team for 19 years product experience and make sure the delivery time.

3.The main components are mainly the international brand, stable and safe.

4.We have professional after-sales teams, and solve the customer problem in time.

1. Factory direct delivery goods and no agent.

2. 24 hours of technical service online

3. Free workpiece test and send test video to you.

4. 19 year experience in product making and application

5. In stock, 12 months warranty periods

6. Lifetime technical and accessory support

In induction heating, due to power grid fluctuations, environmental changes, the impact of human factors, for mass production quality is difficult to guarantee, and energy compensation monitoring system by setting the work piece heating qualified energy benchmark range, the work piece heating process to give the corresponding energy compensation, and display detection records, make the corresponding control, so as to ensure product quality.

Get Started

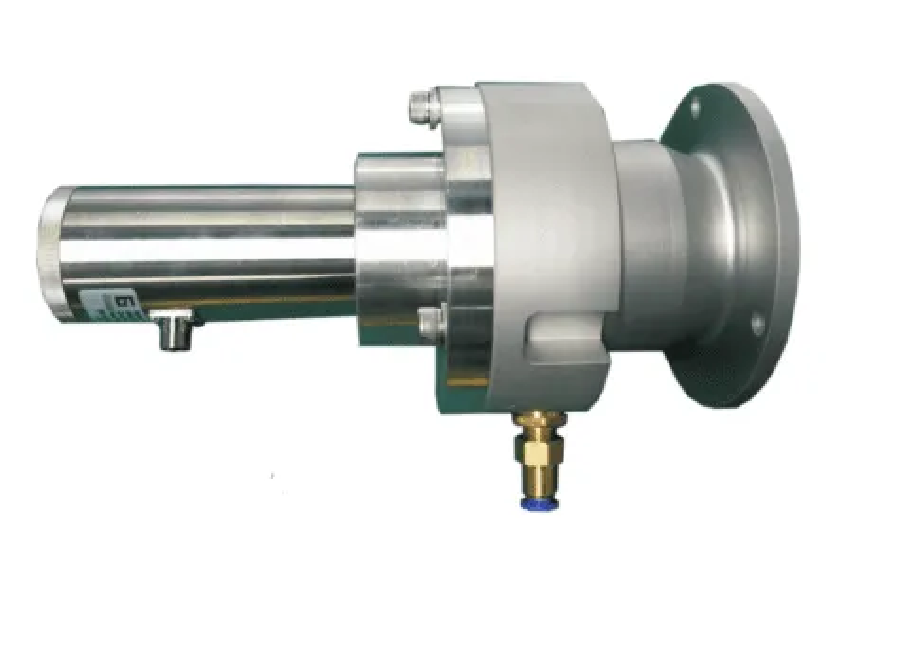

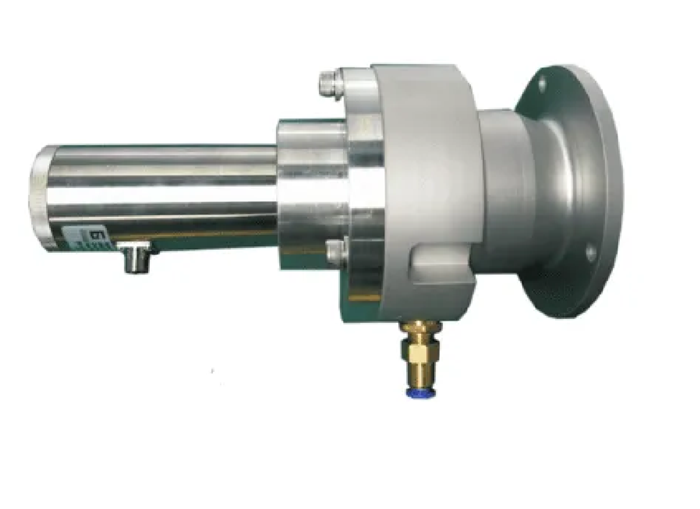

It can measure temperature for a long distance with a laser beam to indicate the measurement direction.

Get Started

The infrared detect machine, can be equipped to any model of our induction heating machine, so it can detect the temperature and control the temperature. Any object has infrared radiation, the intensity of which varies with temperature. The wavelength range of thermal radiation used in infrared temperature measurement 1 mum - 20 microns.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible