1. The highest heating speed is less than 1 second.

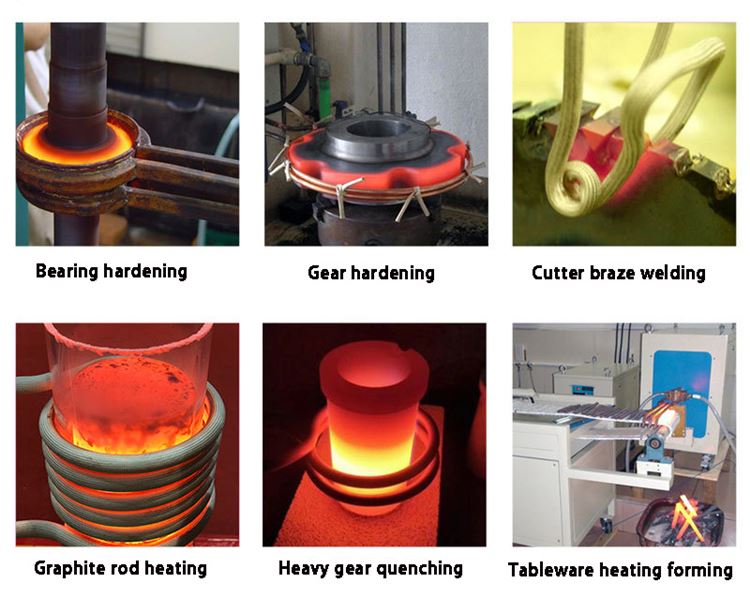

2. Can heat all kinds of different metal workpieces.

3. Energy-saving: It saves 70% more power than the old vacuum tube high frequency induction heaters.

4. Perfect self-protection function has over-voltage, over-current, lack of water alarm indicators

5. Through the set heating time to control the workpiece heating temperature.

6. Full load design, can work 24 hours continuously.

7. Small volume, light weight, green environment.

|

Model |

Max. Input power |

Max. Input current |

Frequency |

|

FHG-25 |

25KW | 38A | |

|

FHG-120 |

120KW | 180A | 20-80KHz |

|

FHG-160 |

160KW | 250A | |

|

FHG-200 |

200KW | 250A | |

|

FHG-250 |

250KW | 380A |

1. Variable frequency adaptive: Magnetic Induction Heater frequency range is 0.2KHZ-50KHZ, after process adjustment and load changed, the power frequency will automatically track to the load optimal resonant frequency.

2. Automatic power regulation: 10%-100 power level adjust freely.

3. High power factor: more than 95%.

4. 100% startup success rate.

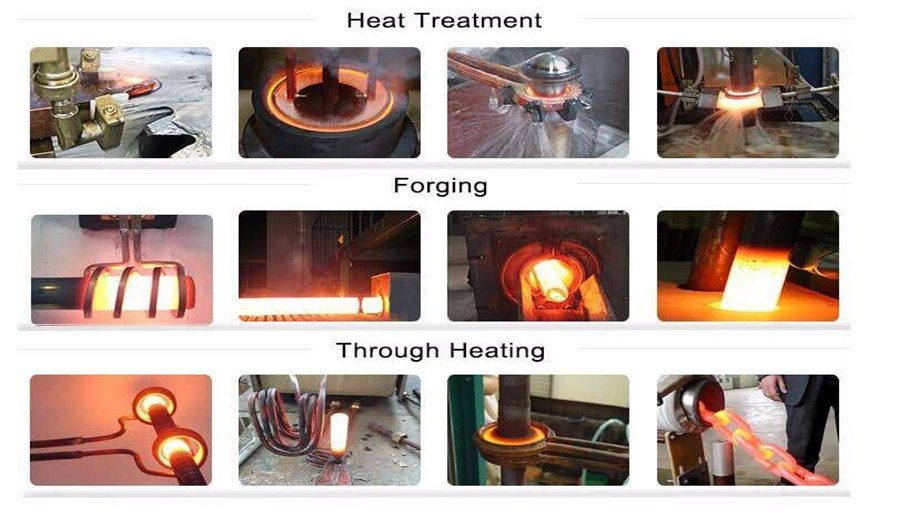

1. Carbon steel screws and stainless steel screw heated glue.

2. Saw blades continuous quenching, stainless steel, annealing or quenching.

3. Weld metal pipe joints, continuous welding.

4. For the shaft, gear hardening, inner hole hardening, hardening depth can reach less than 2mm

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

5.What are your payment terms?

Pay 30% T/T as advanced payment, the balance amount can be paid before shipment.

1. We are the top induction heating machine supplier, no agents.

2. We have strong technical team for 19 years product experience and make sure the delivery time.

3. The main components are mainly the international brand, stable and safe.

4. We have professional after-sales teams, and solve the customer problem in time.

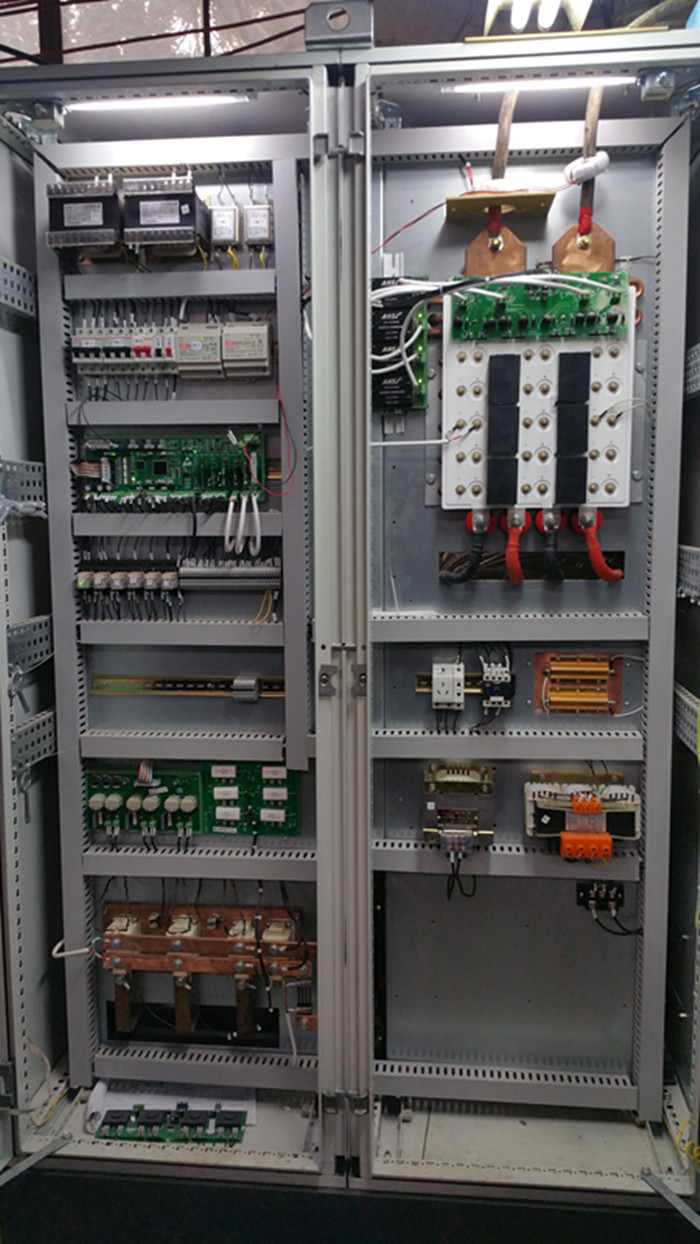

Induction surface hardening machine details : Power module provides high frequency alternating current, usually using IGBT or MOSFET and other power devices. Induction coil produces alternating magnetic field, shape and size according to the workpiece design. Control system adjust frequency, power and other parameters to achieve accurate control. Cooling system to prevent equipment overheating, commonly used water cooling or air cooling.

Get Started

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Melting equipment is mainly used for the steel, alloy steel, cast iron and other ferrous metal materials and stainless steel, copper, aluminum, zinc and other non-ferrous metal material smelting.

Fill in the information and we will contact you as soon as possible