1. Can work 24 hours with full load design

2. It has self-protection function like over current, over heat, phase lack, lack of water alarms.

3. Low energy consumption, easy to install and operate,Medium Frequency induction heaters adopt IGBT series inverter circuit, has high load adaptability.

4. Has big power, fast heating speed, high heating efficiency, and easy operation features.

5. Compare with another heating method, it can significantly promote the economic benefits, improve the quality of the heated parts and save energy and cost, alleviate labor intensity, and improve the production environment.

|

Model |

Input power |

Output voltage |

Oscillation frequency |

Duty cycle |

|

FHZ-25 |

25KW |

70-550V |

200-2000KHz |

24 hours continuous working |

|

FHZ-45 |

45KW |

70-550V |

200-2000KHz |

|

|

FHZ-70 |

70KW |

70-550V |

200-2000KHz |

|

|

FHZ-110 |

110KW |

70-550V |

200-2000KHz |

|

|

FHZ-160 |

160KW |

70-550V |

200-2000KHz |

|

|

FHZ-240 |

240KW |

70-550V |

200-2000KHz |

|

|

FHZ-500 |

500KW |

70-550V |

200-2000KHz |

1.Complete service system before and after sales, professional heattreating engineers, make sure that you have no problem of technique and skills.

2.Hundreds kind of machines are available, you can find proper machine for every kind of modules.

3.Comparing to electronic tube, it saves 50% energy;comparing to thyristor,it saves 20% energy.

4.Low cost of making induction coils, wide-matching performance,various function of technological planning, making your usage more freely.

5.Small volume,light weight , easy to remove, it has non high voltage, make operation more safely.

6.Digital auto-control, it has the function of manual, semi-auto,full-auto and heating-keeping-cooling divide period to control.

7.Perfect function of protect itself, such as over-voltage, over-current, lack of water, phase fail,over hot,etc.

8.Auto tracking frequency itself,the power can be adjusted to max.

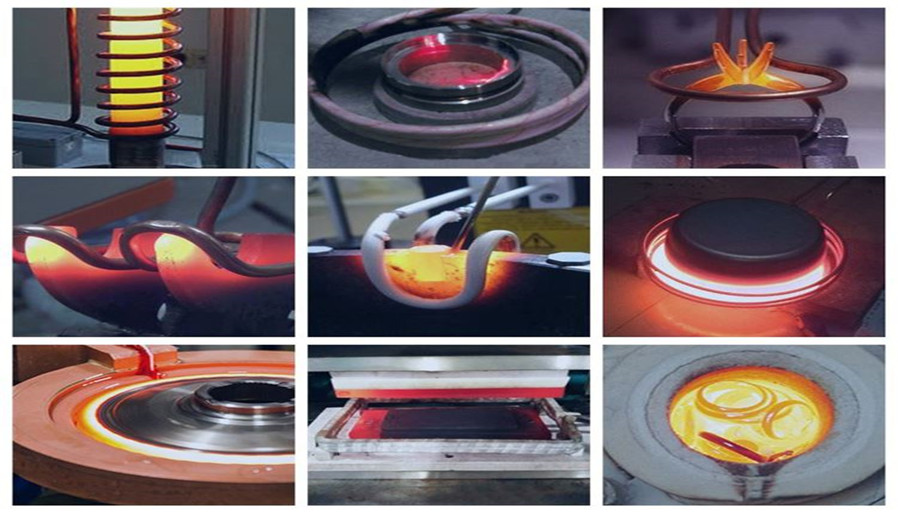

Medium frequency induction heater has wide application ranges during the productions. As per the customer’s technical request, we do the different induction heating technical designs to meet different application fields.Such as, heat treatment, brazing, melting files and so on.

1.We are the top induction heating machine supplier, no agents.

2.We have strong technical team for 19 years product experience and make sure the delivery time.

3.The main components are mainly the international brand, stable and safe.

4.We have professional after-sales teams, and solve the customer problem in time.

Delivery time: in 10-15 working days.

Warranty period: 12 months.

Payment terms: 30% T/T, before shipment 100% T/T should be paid.

Package: plywood cases.

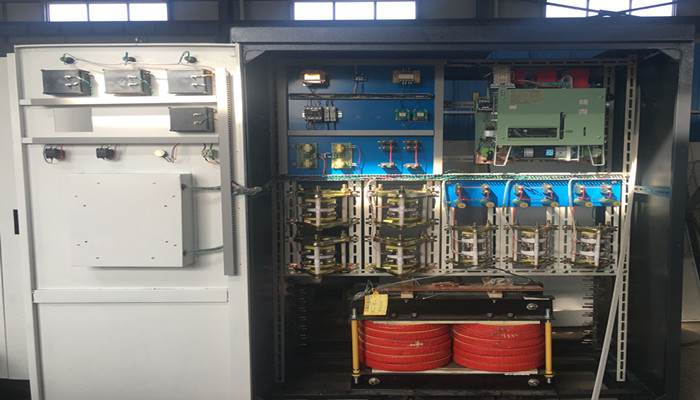

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

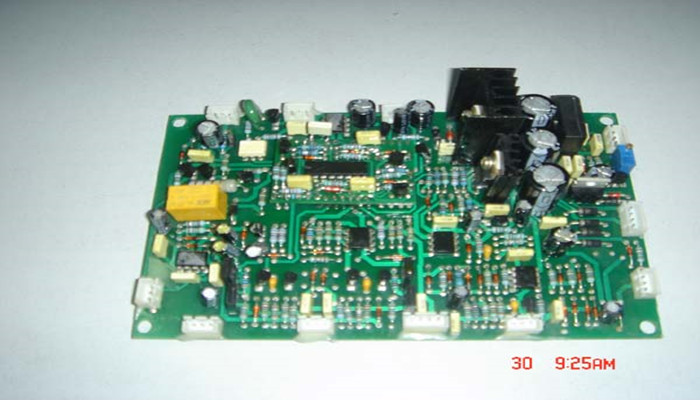

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Fill in the information and we will contact you as soon as possible