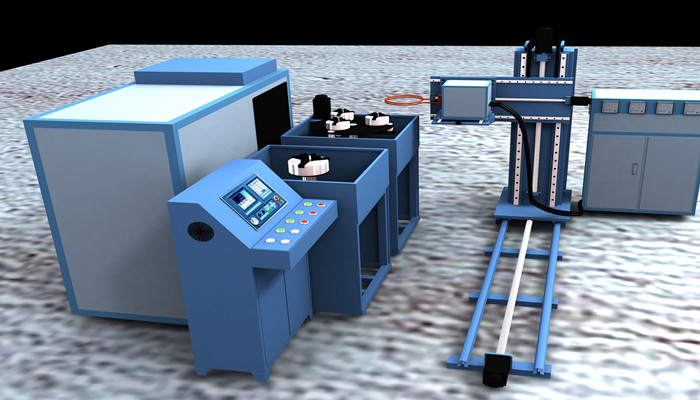

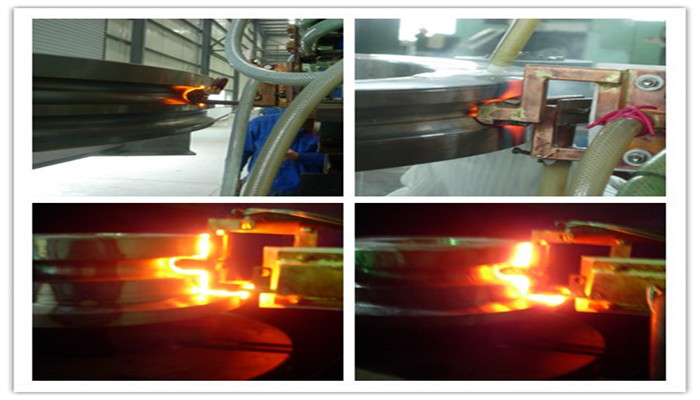

The ring hardening machine is used for the whole ring gear hardening and ring gear single tooth hardening jobs. It consists of induction heating machine, CNC hardening machine tool, cooling water, transformer, induction coils. According to different parts request, changing the different induction hardening coils is OK.

Ring induction hardening machine is used for the bear inner raceway, outer raceway continuously scanning hardening, single teeth induction hardening project. We could do the product range as follow.

1.Max. Heated parts diameter range: 300-5000mm

2.Max. Heated parts height: 400mm

3.Max. Heated parts weight: 500kg

1.Use DSP digital heating machine, match hardening transformer, can work with different size induction coils, though adjusting the load matching to reach the perfect heating result

2.The hardening transformer and induction coil moves with the servo motor drive, moving guide is the linear guide, the moving position can be precisely controlled.

3.The CNC hardening tool adopts a gantry type structure, can realize the coil radial moving. On the moving beam design induction coil lifting and lateral moving slide table can realize the coil lifting and horizontal moving.

The customer can send the workpiece to us, we can make suitable induction coil to heat your workpiece and checkout heating result.

After sales1.We can provide technical support for all of our induction heating machine installation and debugging.

2.We will regularly follow up with users and provide heat treatment process improvement.

3.Our machine warranty period is one year, after that, we could continue to provide favorable machine accessory.

|

Power range |

5-400KW |

|

Frequency range |

20-80KHZ |

|

Power factor |

>0.95 |

|

Resonance mode |

series resonance |

|

Power adjustment mode |

frequency modulation, pulse density modulation |

|

Control mode |

analog circuit |

|

Control precision |

>1% |

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get Started

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible