1.A high degree of automatic can achieve automatic operation

2.Induction furnace body is easy to replace.

3.The heating speed is fast and the oxidation takes off less carbon.

4.Select automatic feeding and discharge sorting device, optimize the design of dozens of parameters of the induction coil, referring to the design concept of a foreign induction coil, we make the induction coil with high heating efficiency , short furnace length, a small loss.

1.Digital constant power control system

2.Various self-protection functions (over current, over heat, lack of water, lack of phase,etc)

3.Easy to operate and maintenance

4.The circuit gets rid of the tedious starting circuit and relay circuit.

5.Smooth adjustment curve, high linearity, no impact

6.According to the change of load to adjust the transformer matching, save power.

Power:30KW—1000KW

Frequency: 0.5KHz—20KHz

When heating standard parts,fasteners for forging, if diameter more than 20mm,medium frequency is proper. If use HF this time, modules must be heated melting external,but internal not heated.So it’s not effective,also age of mold induces,the cost increase a lot.

Hot forging is mainly to heat the workpiece to a certain temperature (according to the different material heating temperature is different), through the punch, forging, or other forms of the workpiece into other shapes.

For example: watch case, table blank, mold accessories, crafts, standard parts, fasteners, copper lock and so on.

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

5.What are your payment terms?

Pay 30% T/T as advanced payment, the balance amount can be paid before shipment.

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

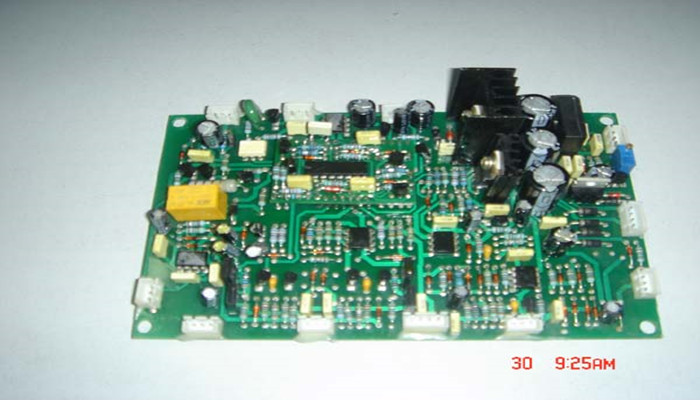

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible