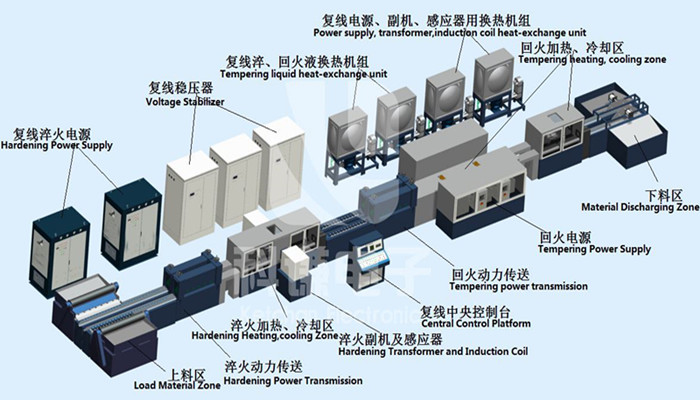

We have supplied several piston rod induction hardening tempering lines for some factories. And the complete induction hardening tempering system configuration is as below:

1.Horizontal CNC Induction Hardening Tempering Machine Tool

2.IGBT high-frequency induction heating machine

3.IGBT high-frequency induction heating machine

4.Cooling water circulation system

5.Induction hardening coil

Pistons rods induction hardening tempering applications, doing 1 piece each time, and doing 2 pieces each time.

Piston rods specification: diameter 18-22mm, length 350-500mm, heat-treating length 184-334mm.

Hardening depth: 1.0-1.3mm.

Material: S45C.

1.We are the top induction heating machine supplier, no agents.

2.We have strong technical team for 19 years product experience and make sure the delivery time.

3.The main components are mainly the international brand, stable and safe.

4.We have professional after-sales teams, and solve the customer problem in time.

|

No. |

Item Name |

Parameters |

|

1 |

The main body of the production line |

|

|

1.1 |

Adapt to workpiece diameter range(mm) |

Φ18~Φ22 |

| 1.2 |

Adapt to the maximum length of the workpiece(mm) |

500 |

| 1.3 |

Top servo moving distance(mm) |

700 |

| 1.4 |

Workpiece rotation speed( r/min) |

20-100 Continuously adjustable |

| 1.5 |

Central top working speed (mm/s) |

2-200 Adjustable |

|

2 |

Heating Power Supply:100KW/100KHZ |

|

| 2.1 |

Power Type |

IGBT |

| 2.2 |

Rated Power (kw) |

100KW |

|

3 |

Load System |

|

|

3.1 |

Transformer two-dimensional (X / Z direction) manual distance adjustment:mm |

±30 |

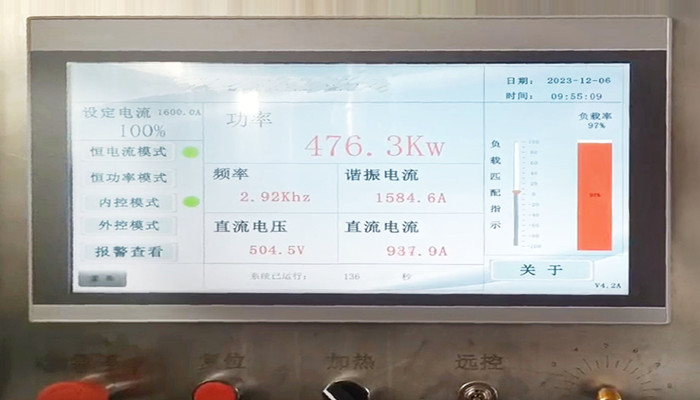

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

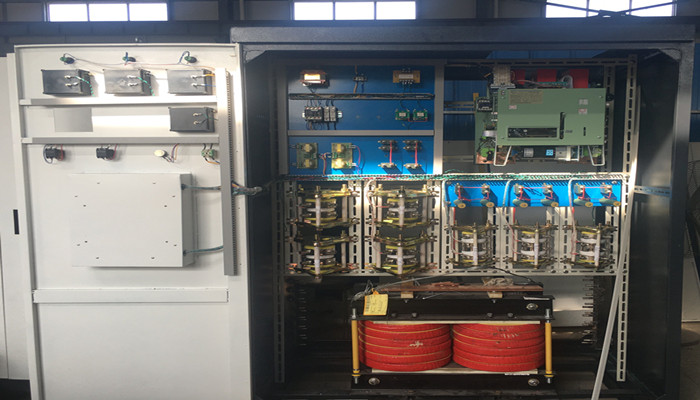

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible