1. Our High Frequency (HF) Hardening Machine adopts IGBT solid-state inverter technology.

2. 100% duty cycle, can 24 hours continuously working.

3. Digital phase lock technology, automatic frequency tracking.

4. Modular design, easy installation, and operation.

5. Perfect self-protection functions, stable working, and easy maintenance.

Power:8KW—600KW

Frequency: 0.5KHz—500KHz

Load impedance good or bad is very important to machine run in gear.Brought machine of impedance range narrow, arose localizing in using ,so much as trouble ceaseless.

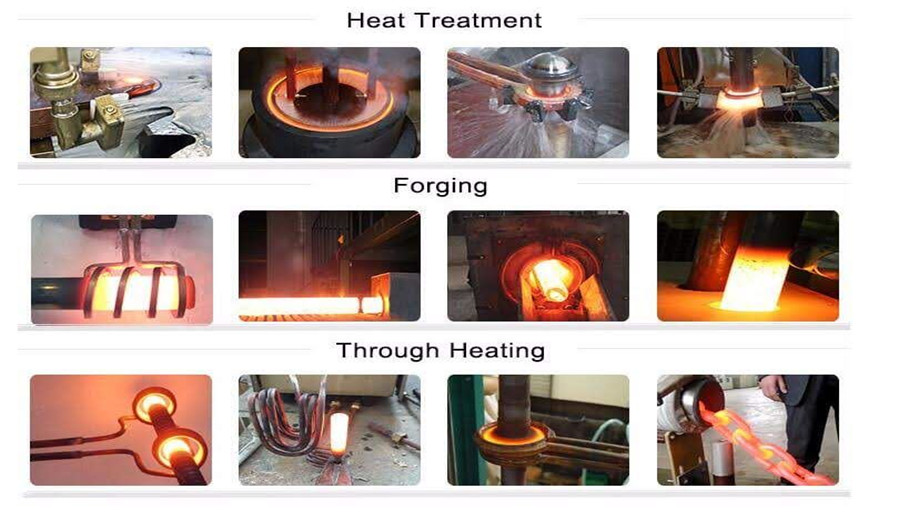

High frequency induction furnace is used for all kinds of metal parts high-frequency induction quenching hardening treatment,brazing ,etc.

1. We are the top induction heating machine supplier, no agents.

2. We have strong technical team for 19 years product experience and make sure the delivery time.

3. The main components are mainly the international brand, stable and safe.

4. We have professional after-sales teams, and solve the customer problem in time.

1. Factory direct delivery goods.

2. 24 hours of technical service

3. Free workpiece test

4. 19 year experience in product making and application

5. In stock, 12 months warranty periods

6. Lifetime technical and accessory support

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get Started

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

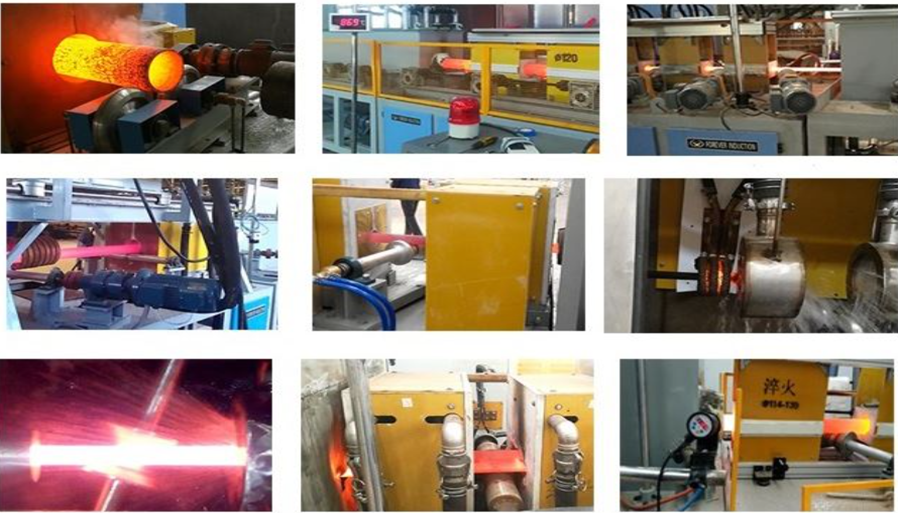

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Medium frequency pipe bender adopts medium frequency induction heating machine heating to bend the workpiece under the condition of local heating.

Fill in the information and we will contact you as soon as possible