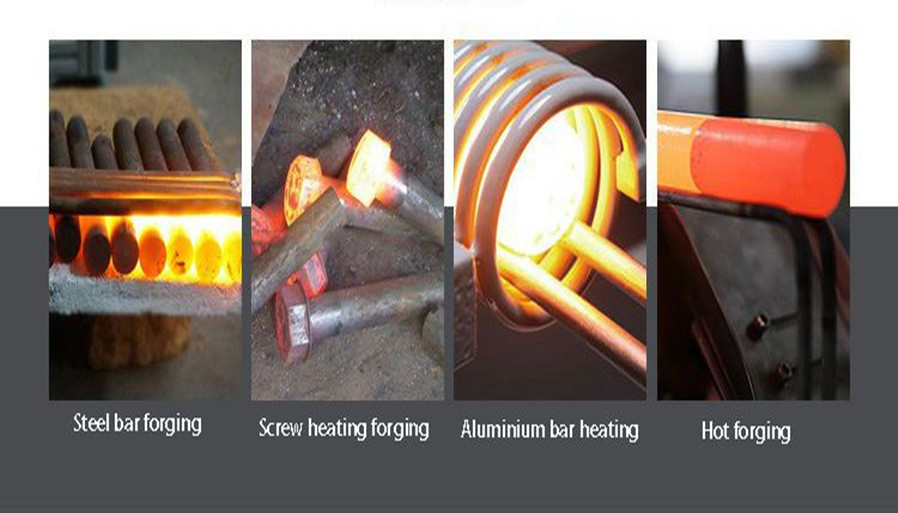

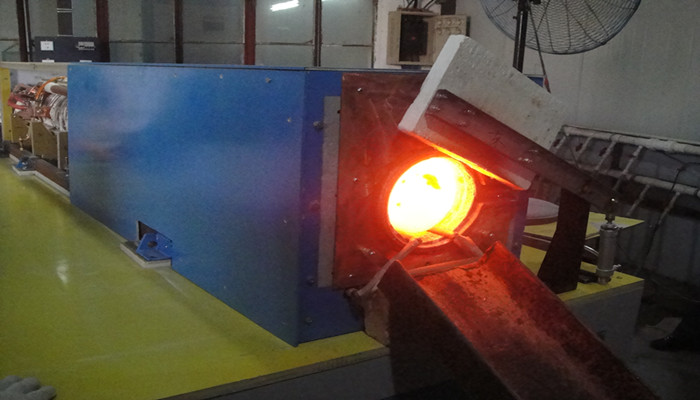

1.The induction forging furnace is widely used in metal heating forging applications. Like the round bar, square billet, steel plate forging projects.

2.High heating speed, high production efficiency, less oxidation

3.Superior working environment, improve workers’ working environment and company image, no pollution, low energy consumption.

4.Energy-saving, small burning loss, easy to start.PLC control, touch screen man-machine interface, flexible operation, high reliability, easy maintenance, easy to upgrade.

1.Easy to start: empty furnace start, empty furnace stop, no waste

2.Instant use: Out of the box, any temperature (cold/hot), any load fast start. Cold furnace heating time is short, material preparation speed is fast.

3.High efficiency and energy saving: no separate reactive power compensation, high power factor 0.96

4.Heat preservation function: When the forging is suspended, the standby state can be maintained to minimize the waste loss.

5.Automatic multi-purpose: one power supply is suitable for matching a variety of different specifications of induction furnaces and billets, automatic matching.

6.Rapid heating: The rapid heating time of aluminum is short, the starting time is measured in seconds, and the heating temperature uniformity is high.

|

Rated power(KW) |

Rated frequency(Hz) |

Transformer |

Induction |

Power consumption |

Billet diameter(mm) |

Volume(KVA) |

|

3000 |

400-1500 |

3500 |

850 |

2800 |

350 |

800-1000 |

| 2000 |

500-1500 |

2200 | 850 | 1200 | 360 | 400-800 |

| 1500 |

500-1500 |

1600 |

660-380 |

1200 | 370 | 250-400 |

| 1000 |

500-1500 |

1250 |

660-380 |

1200 | 380 | 150-250 |

| 500 |

500-800 |

630 |

660-380 |

800 | 450 | 120-150 |

| 250 | 1000-8000 | 400 |

3*380 |

800 | 450 | 60-80 |

| 100 | 1000-8000 | 100 |

3*380 |

800 | 450 | 25-40 |

1.Check and maintain the equipment regularly, check and tighten the bolts and pressing parts of each part.

2.Periodically check the over current value and over voltage value of the device, check the reliability of the operation of the protection system.

3.Frequently check whether the water pipe joint is firm, timely clean the scale, and plug in the cooling water pipe.

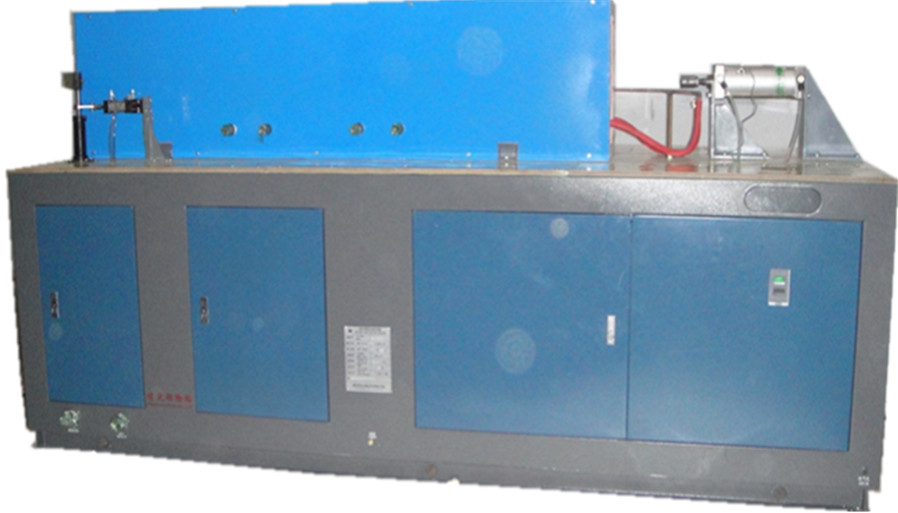

IGBT induction hot forging heater is mainly used in bar forging. It has part forging and whole bar forging. According to different workpiece technical request, we suggest suitable machine for you.

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

5.What are your payment terms?

Pay 30% T/T as advanced payment, the balance amount can be paid before shipment.

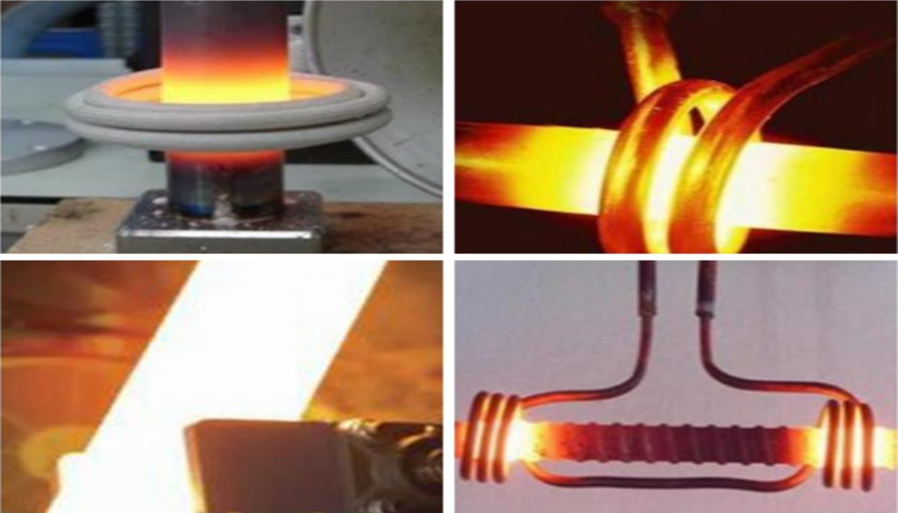

Induction forging furnace is the core component of induction heating equipment, which is responsible for generating alternating magnetic field to induce eddy current inside the metal workpiece and heat. Main structure: Coil material: usually high conductivity copper pipe, internal cooling water to prevent overheating. Coil shape: According to the shape of the workpiece design, common spiral shape, flat shape, ring and so on. Insulation: The coil surface is coated with insulation to prevent short circuits and arcing.

Get Started

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get Started

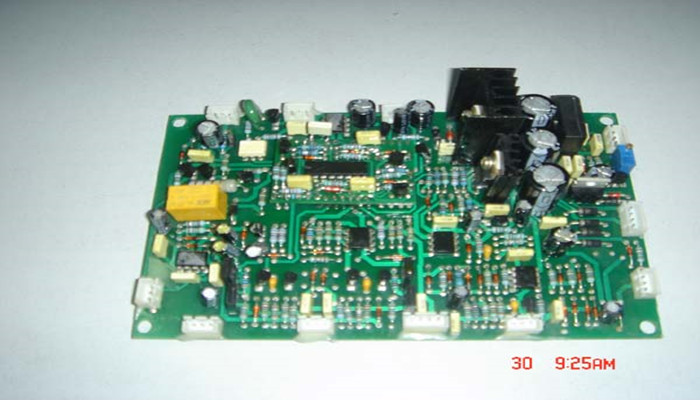

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible