UHF induction heating equipment adopts IGBT inverter control technology, machine frequency range 80-200kHZ, suitable for all kinds of metal parts heat treatment projects. All the equipment can customized different voltage range like single phase 220V, three phase 380V, 440V,and 480V.

|

Model |

Max. Input Power |

Frequency |

Memo |

|

FHC-10 |

10KW |

80-250KHZ |

One Body |

|

FHC-20 |

20KW |

80-200KHZ |

Split Body |

|

FHC-30 |

30KW |

80-180KHZ |

|

|

FHC-60 |

60KW |

80-150KHZ |

|

|

FHC-100 |

100KW |

||

|

FHC-120 |

120KW |

50-120KHZ |

|

|

FHC-160 |

160KW |

1.To prevent electric shock, ensure that the electrical specifications of the chassis are reliably grounded.

2.Disassembly and installation of the induction coil must be carried out after reheating is stopped.

3.Strictly implement the principle of connecting water first and then the power on, water shortage is strictly prohibited in the working process, and the quality and pressure of cooling water used in the equipment and induction coil must meet the requirement in Table 2. To avoid blocking the cooling pipes, if a water pump is used for water supply, install filter cooling water at the water pump inlet. The temperature should not be higher than 45℃, and the water flow should be 10T/H

4.The machine must be protected from sunlight, rain, humidity, and dust. When the device needs to be repaired or maintained, it must be repaired after the power if off.

5.Clean the machine with compressed air or a fan every week. The circuit board is cleaned with a brush and then blown clean.

6.Ordinary users should be used it every 4 months with special detergent to clean the machine once.When the machine frequently alarms water temperature, or observe the water flow at the outlet significantly reduced should be cleaned immediately.

7.The induction coil should be kept clean to prevent a short circuit between turns.

8.The ultrahigh frequency induction heating machine cannot use a single turn sensor. Otherwise, the device may be damaged due to too small inductive reactance. In special cases, please consult the manufacturer.

9.When replacing the induction coil, the induction coil connecting plate and the transformer contact surface should be sanded clean to maintain good conductivity.

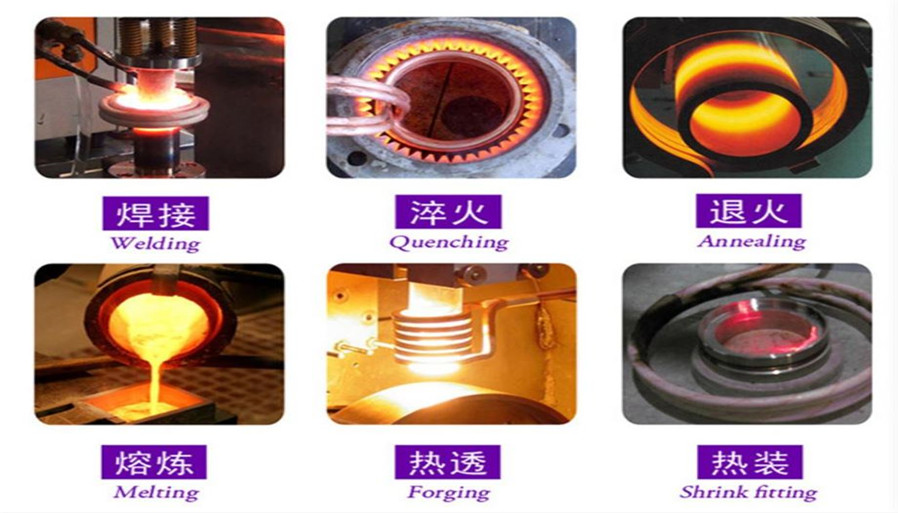

1. All kinds of gear and shaft heat treatment.

2. Carbon steel screws and stainless steel screws heated glue.

3. Magnetic suspension induction melting.

4. Wire and pipes continuous heating annealing.

5. All kinds of gear and shaft heat treatment.

1.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

2.Can you customized the logo, color and others?

Yes, we can.

3.How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

4.Does the quotation include freight?

The quotation is usually the arrival port for export to domestic ports. You could also arrange to your freight forwarding.

5.What are your payment terms?

Pay 30% T/T as advanced payment, the balance amount can be paid before shipment.

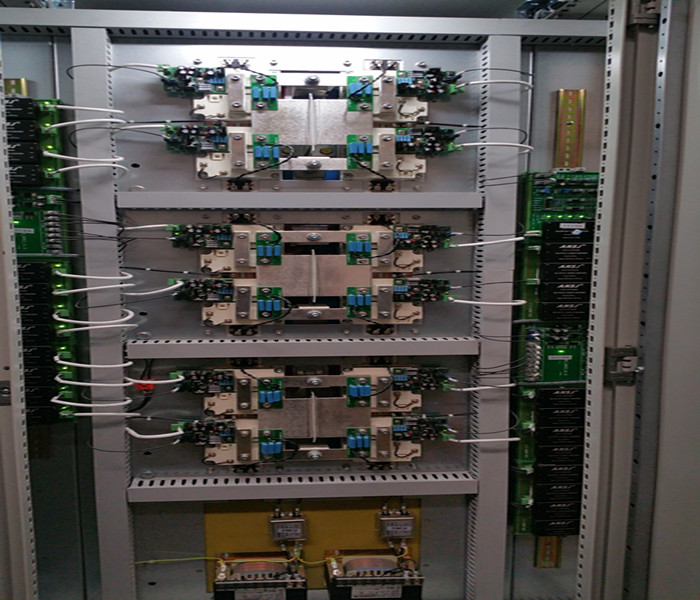

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

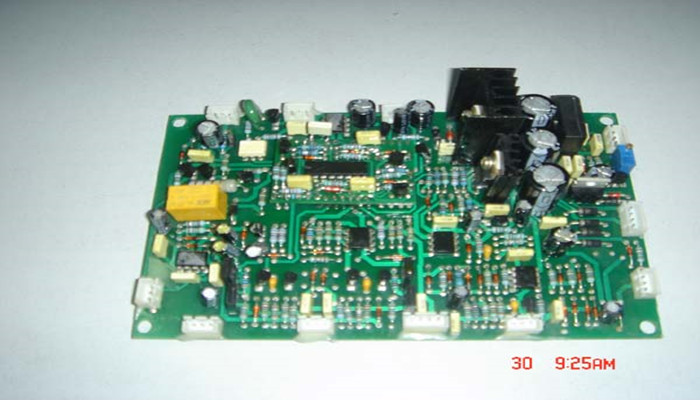

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible