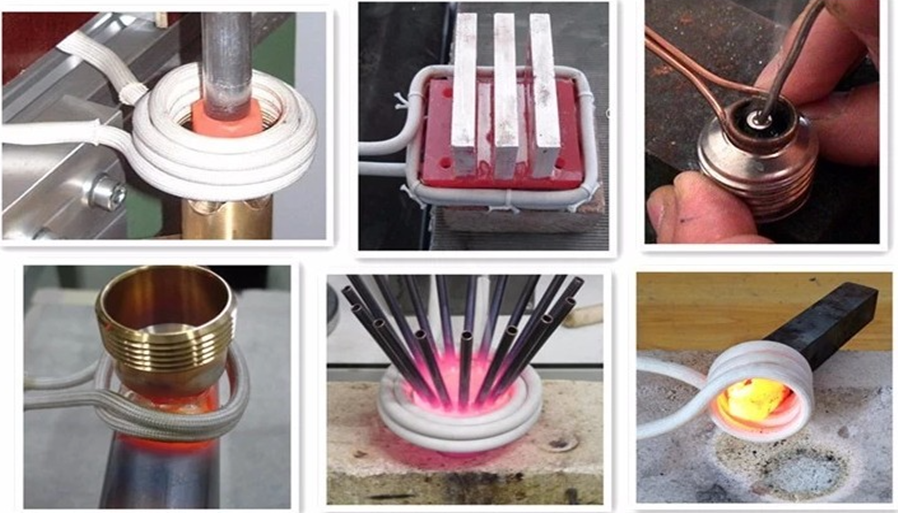

Because the heating materials, magnetic induction performance varies greatly, the heating requirements are different, and the shape and size of the induction ring are different as well, so the handheld brazing equipment needs to be adjusted accordingly to achieve good heating effects. At present, most of our FHY3 handheld brazing equipment has been developed for braze welding copper pipes, and this equipment may not be suitable for other purposes. Therefore, when ordering equipment, we need to provide the corresponding information:

(1)The heating workpiece material and size.

(2)Heating purpose and heating temperature, as well as heating time requirements and other information? So that we can suggest suitable handheld induction brazing machine models.

|

Main Model |

Max. Oscillating Power |

Induction Heater Configuration |

Input Voltage |

Coil Max current |

|

FHY3-05 |

5KW |

Induction heater with the water tank |

Single-phase 220V |

450A |

|

FHY3-10 |

10KW |

Induction heater with chiller |

Three phases 380V |

800A |

|

FHY3-18 |

18KW |

Induction heater with chiller |

1100A |

|

|

FHY3-30 |

30KW |

Induction heater with chiller |

||

|

FHY3-40 |

40KW |

Induction heater with chiller |

1.Automatic billet feeding device, save energy, protection environment

2.Different shape billet just need to change different induction furnace, the furnace is easy to change.

3.Heating uniform, heating speed is faster.

4.Match with an independent cooling water circulation system to ensure the machine can 24 hours continuously working.

5.Perfect self-protection functions, like over-voltage, over heat, lack of water, lack of phase, etc.

This handheld copper induction brazing machine’s built-in chiller, PLC control, and touch screen operation panel, this integrated handheld heater is easy to install. It is mainly used in the copper tubing, copper fittings industry brazing welding jobs.

1.The handheld induction brazing equipment’s heating head is small and light. It is also convenient to operate the heating by the multi-joint robot hand.

2.Heating head is durable, not easy to damage, and easy to maintain. Heating head inside only one or two resonant capacitors, simple water cooling, simple structure, strong and durable.

3.High heating efficiency and energy saving.

4.FHY3 handheld induction brazing equipment is generally designed for special purposes, and the range of heating materials and induction rings is limited. If you have other braze request, please tell us.

Induction brazing welding: Normally with brazing welding, silver brazing, copper brazing, and so on.

1.We are the top induction heating machine supplier, no agents.

2.We have strong technical team for 19 years product experience and make sure the delivery time.

3.The main components are mainly the international brand, stable and safe.

4.We have professional after-sales teams, and solve the customer problem in time.

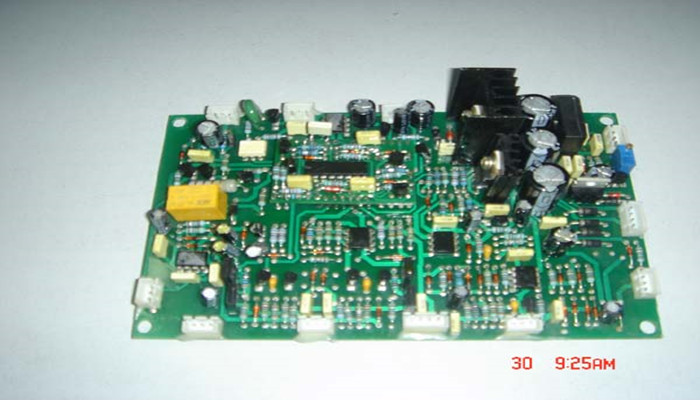

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible